TM 9-4310-397-14

(f)

When installing new rings from service parts, use a Piston Ring Expander. Install oil ring expander in

bottom ring groove. Position end gap over either end of piston pin.

(g)

Install oil control ring in bottom ring groove over ring expander. Install with end gap on opposite side of

piston from ring expander gap.

(h)

Rectangular compression ring is marked to identify top side of ring. Install rectangular compression ring

in center ring groove with mark toward top of piston.

(i)

Position gap in rectangular compression ring on opposite side of piston from oil control ring gap.

(j)

Keystone compression ring has a mark to identify top side of ring. Install keystone compression ring in

top ring groove with mark toward top of piston.

(k)

Position gap in Keystone compression ring on opposite side of piston from rectangular compression ring

gap.

(l)

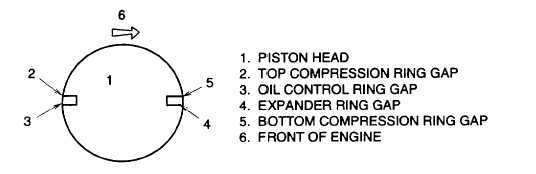

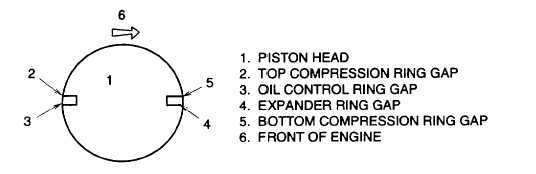

Stagger ring gaps on pistons as shown. If crankshaft was removed, install crankshaft per paragraph 6-11.

Figure 6-91. Ring Gaps

(m)

Coat pistons, liners and inside ring compressor (item 4, section III, appendix B) with oil (item 10, section

II, appendix E).

(n)

Carefully place ring compressor with piston and rod over liner.

CAUTION

Be sure crankshaft journals and liner walls are not damaged when installing

piston and rod in liner.

NOTE

Be sure the word "front" on rod faces toward the front of the engine.

(o)

With piston centered in installing tool and rings staggered correctly, push piston (Figure 6-92, 1) into liner.

6-77