TM 9-4310-397-14

6-11. CRANKSHAFT, PULLEY, IDLER GEARS, AND MAIN BEARINGS INSPECTION, REPAIR AND

REPLACEMENT. - Continued

(b)

Remove main bearing caps.

NOTE

Visually inspect condition of bearing inserts as bearing caps are removed. Keep

caps and inserts together and in correct order.

(c)

Check main bearing clearance.

1

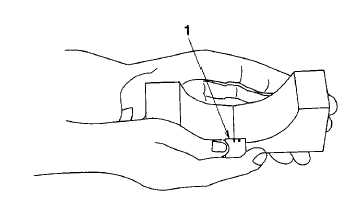

Place a strip of bearing clearance gauge (items 21, 22, and 23, section II, appendix E) (Figure 6-98,

1) in the center of the main bearing cap about three-fourths of the width of the bearing.

Figure 6-98. Main Bearing Clearance

2

Use oil on bearing clearance gauge to prevent smearing.

3

Install cap and torque to 85 ft-lb. (120 Nm).

NOTE

The use of bearing clearance gauge will determine wear, but will not determine

condition of either bearing or journal.

4

Remove cap and compare width of bearing clearance gauge with scale provided to determine

clearance. Maximum permissible clearance 0.006 in. (0.15 mm).

(2)

Remove crankshaft.

WARNING

Do not attempt to remove crankshaft by hand. Use proper lifting equipment to

avoid personal injury and damage to equipment.

(a)

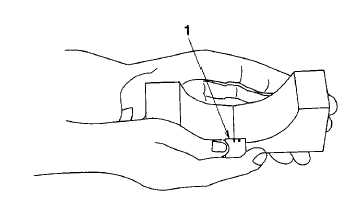

Attach a nylon sling (or other suitable lifting sling) to journals of crankshaft (Figure 6-99, 1).

6-82