TM 9-4310-397-14

6-11. CRANKSHAFT, PULLEY, IDLER GEARS, AND MAIN BEARINGS INSPECTION, REPAIR AND

REPLACEMENT. - Continued

(b)

Use a soft wire (Figure 6-107, 1) and compressed air to clean orifice. Replace, if condition is

questionable.

CAUTION

A piston cooling orifice failure could cause damage to pistons, piston pins, rod

pin bushings, and liners. If a piston cooling orifice is left out, low or no oil

pressure will result.

(c)

Install all the orifices and torque to 84 lb-in (10 Nm).

(3)

Install main bearings and crankshaft.

(a)

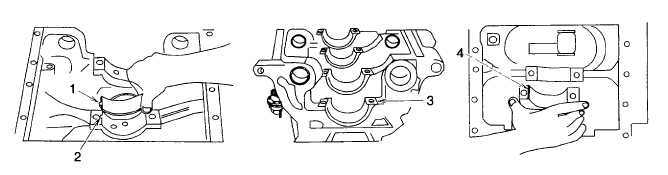

Install main bearing inserts. Make sure that tang (Figure 6-108, 1) on the inserts is engaged with slot (2)

in the cylinder block and main bearing caps. Also make sure that oil holes line up with oil passages in

block.

Figure 6-108. Install Main Bearings

NOTE

If new thrust bearing inserts or thrust bearing washers are installed, they must be

installed as a set.

(b)

Install main thrust bearing (3)

in rear web of cylinder block.

(c)

Apply a liberal coating of clean engine oil (item 10, section II, appendix E) to bearing surfaces and

crankshaft journals.

(d)

Using proper lifting equipment, lower crankshaft onto main bearings.

(e)

Dip entire main bearing cap screws in clean engine oil and position them in the main bearing caps. Apply

a liberal amount of oil to bearing inserts in caps.

(f)

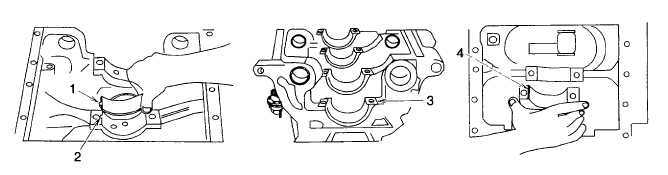

Install each bearing cap, bearings (4) and cap screws with washer with the recesses and tabs aligned in

matching order. Make sure bearing tabs also match up before tightening cap screws.

6-88