TM 9-4310-397-14

2-5. OPERATING PROCEDURES. - Continued

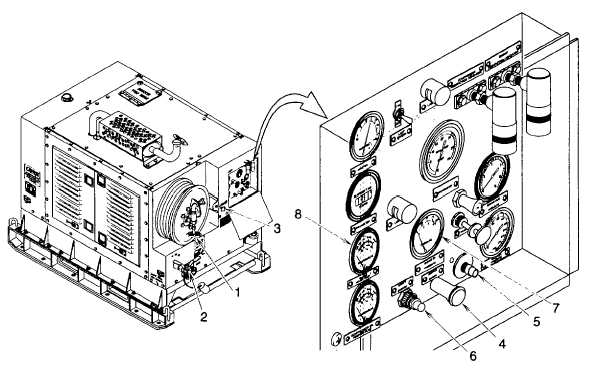

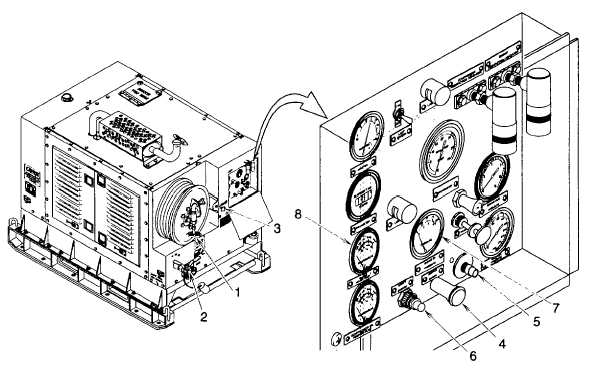

Figure 2-3. Unit Operation, Usual

(6)

Depress SAFETY BYPASS switch (6) and hold. Pull IGNITION-START switch (4) and release when

engine starts. When pressure is indicated on ENGINE OIL PRESSURE gauge (7) release SAFETY

BYPASS switch (6).

(7)

If engine oil pressure does not register within three seconds after engine starts, release SAFETY BYPASS

switch (6), push IGNITION-START switch (4) in and notify supervisor.

(8)

When engine water temperature reaches 140° F (60° C), as indicated on ENGINE WATER TEMPerature

gauge (8), close the hose reel valve (1) and double discharge valve (2) and turn COMPRessor

UNLOADER AND IDLE CONTROL knob (3) counterclockwise until it stops. This action increases engine

speed and opens compressor intake valve to start compression.

CAUTION

Operating the equipment unattended for prolonged periods of time can result in serious

damage to the unit.

(9)

Unit is now ready for use and will cycle through load and unload automatically in relation to air demand.

As demand increases, the engine will accelerate and the compressor will replenish compressed air supply

in the separator tank. As demand decreases, or stops, engine will return to idle and compressor will run in

an unloaded condition until demand for air again causes unit to load.

(10)

Perform all the DURING PMCS as outlined in table 2-1.

2-28