TM 5-4310-354-14

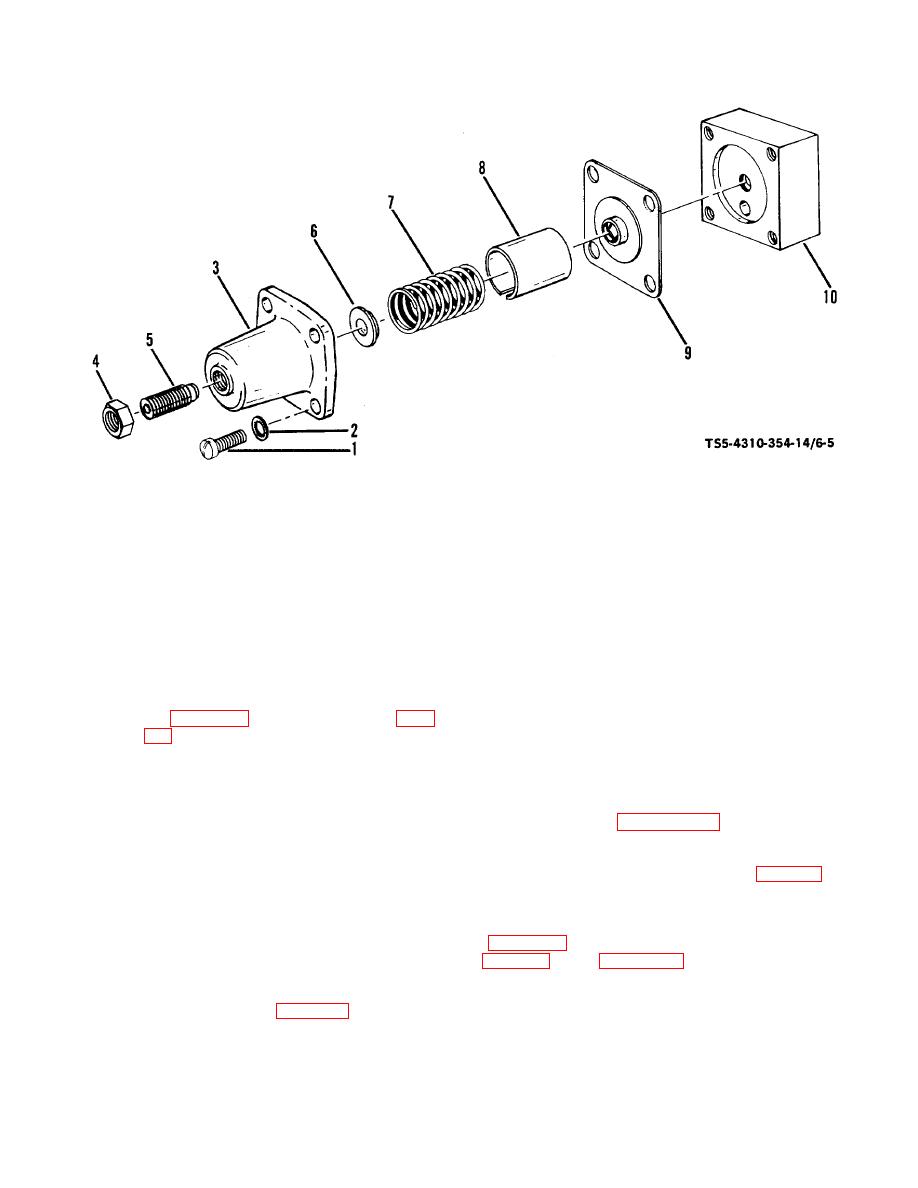

1.

Cap screw (4)

6. Spring seat

2.

Lock washer (4)

7. Regulator spring

3.

Housing

8. Spring tube

4.

Nut -

9. Diaphragm assy

5.

Adjusting screw

10. Regulator base

Figure 6-5. Air pressure regulator assembly, disassembly and reassembly.

(1) Remove four cap screws (1), four lock

(a) Position diaphragm assembly (9) on

washers (2), and housing (3). Remove

regulator base (10) with holes

nut (4) and adjusting screw (5).

aligned and spring guide portion of

diaphragm assembly away from

(2) Remove spring seat (6), regulator sprin g

base.

(7), spring tube (8), and diaphragm

(b) Assemble spring tube (8), regulator

assembly (9) from regulator base (10).

spring (7), and spring seat (6).

(c) Place housing (3) over these

b. Cleaning, Inspection, and Repair.

assembled parts, press down on

housing (3) to seat against base

(1) Clean parts, except diaphragm assembly

(10). Attach housing (3) to base

(9, figure 6-5), in accordance with para

(10) with four lock washers (2) and

5-7.f.

four cap screws (4).

(2) Wipe diaphragm assembly (9) clean with a

(d) Install adjusting screw (5) and nut

clean, lint-free cloth.

(4).

(3) Inspect diaphragm assembly (9) for any

(e) Test and adjust the air pressure

cuts, tears, deterioration, or any other

regulator

in

accordance

with

defect.

(4) Inspect spring (7) for broken coils,

deformation, or any other defect.

(2) Reassemble air pressure regulator on

(5) Inspect all parts for cracks, breaks,

blowdown valve assembly (para 6-6.d).

damaged threads, or any other defect.

(6) Replace all defective parts.

d. Testing and Adjustment.

After installing air

pressure regulator on unit, check air line connections

c. Reassembly.

(1) Reassemble the air pressure regulator

pressure regulator as follows:

assembly in the reverse numerical

sequence shown in figure 6-5 as follows:

6-9