case. The crankcase is a single casting comprising the

1st stage cylinder, the 2d stage cylinder, the oil sump as

well as the, housing for the rotating parts. Located in

the oil sump portion of the crankcase are the drain plug,

rod-cap and tube assembly. The tube assembly serves

to siphon and filter the oil from the oil sump to the gerotor

which pumps the oil to the other portions of the

compressor group. The rod-cap is located at the top of

the oil sump and is used to determine the oil level within

the oil sump. The drain plug is located at the bottom of

the oil sump and is used to drain the oil sump and to

provide an access to the tube assembly.

14. Maintenance

Third echelon maintenance personnel are authorized to

replace the drain plug, preformed packing, rod-cap,

spring tension washer, tube assembly and any attaching

hardware.

a. Removal. Removal of the compressor group is

not required for replacement of components at the third

echelon.

b. Disassembly (fig. 4)

(1) Unscrew the drain plug (7) from the

crankcase and remove the preformed

packing (6).

(2) Rotate the rod-cap (1) and remove it from

the crankcase.

Remove the preformed

packing (2).

(3) Disassemble the two screws (3) and remove

the spring tension washer (4) from the

crankcase.

(4) Unscrew the tube assembly (5), using a

suitable size screwdriver, and remove it from

the interior of the oil sump of the crankcase

c. Cleaning and Inspection (fig. 4).

(1) Clean all metallic parts with dry-cleaning

solvent.

(2) Blow out the tube assembly (5) through both

orifices using compressed air.

(3) Inspect all parts for distortion, cracks,

defective threads or other damage. Replace

if defective.

(4) Replace the preformed packings (2 and 6)

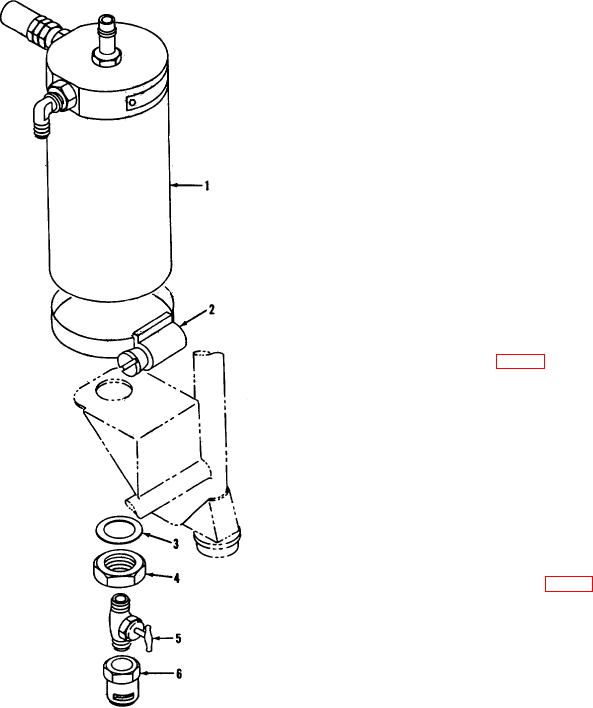

1

Water separator

4

Nut

and the spring tension washer (4).

2

Clamp

5

Needle valve

3

Washer

6

Fitting

Figure 2. Water separator group, exploded view.

addition to the three pressure stages, the compressor

group includes a crankcase section The crankcase

section consists of the crankshaft, keystone, gerotor,

bearings, and a crank-

AGO 648A

7