*TM 3-1040.244-34

c.

Disassembly.

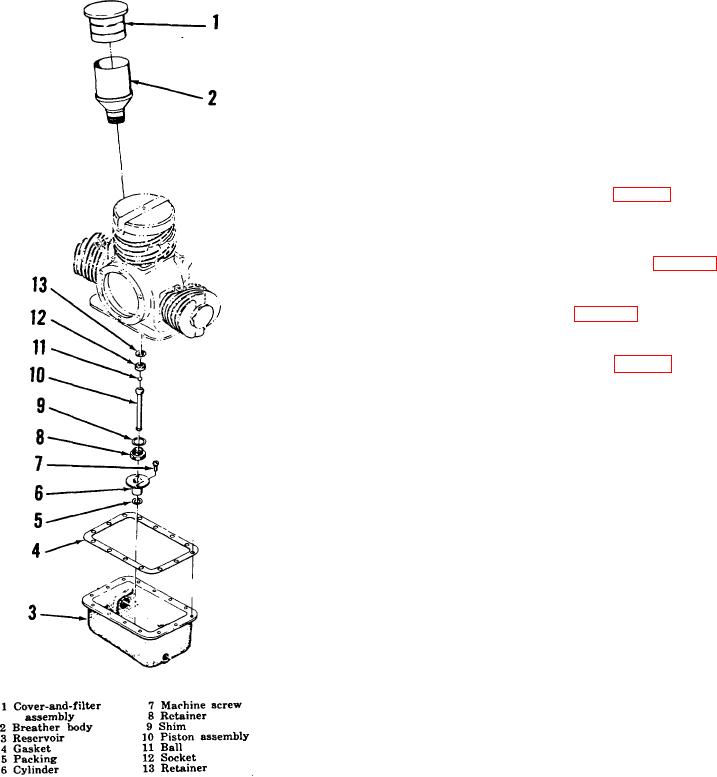

(1) Pull cover and filter assembly (1) from

over breather body (2).

(2) Unscrew

breather

body

from

(3) Remove gasket (4).

Remove two

screws (7) attaching cylinder (6).

Remove cylinder and packing (5).

(4) Cut wire and remove retainer (8), shim

(9), piston assembly (10), ball (11),

socket (12), and retainer (13) from

connecting rod (8, fig. 3-7).

d.

Assembly.

(1) Install parts of oil pump piston repair kit

on connecting rod (8, fig. 3-7) and

secure with wire. Carefully guide end

of oil pump piston into bore of oil pump

cylinder (10, fig. 3-3) positioning gasket

(4) on oil reservoir (3).

Secure

reservoir with 14 screws and nuts.

(2) Install packing (5, fig. 3-3) in groove on

end of cylinder (6) and position both

parts in counterbore inside oil reservoir

(3). Secure parts to reservoir with two

screws (7).

(3) Screw breather (2) into crankcase.

Install cover and filter assembly (1).

3-12.

First Stage Section

a. Description.

The first stage section

consists of an elbow, gaskets, cylinder head, valve stop,

valve spring, valve plate, exhaust valve, intake valve,

cylinder and piston assembly, and attaching hardware.

The first stage cylinder is provided with a cover and air

cleaners which remove particles of foreign matter from

the ambient air drawn into the compressor. Additional

filtering is provided by a strainer and relief valve

assembly installed in the inlet port of the second stage

cylinder. Fine mesh screens installed in the body of the

strainer and relief valve assembly trap solid particles in

the interstage air, and spring-loaded poppets function as

pressure relief valves to prevent interstage air pressures

from exceeding predetermined values. The intake and

exhaust valves used in the first stage of the air

compressor are spring steel flapper-type valves mounted

Figure 3-3. Oil reservoir-and-breather section, exploded

on opposite sides of a valve plate installed between the

view.

cylinder head and the cylinder. The valves are spring

19