Note.

The

cylinder-and-piston

assembly is made up of matched

parts. Do not attempt replacement of

individual parts.

c. Disassembly.

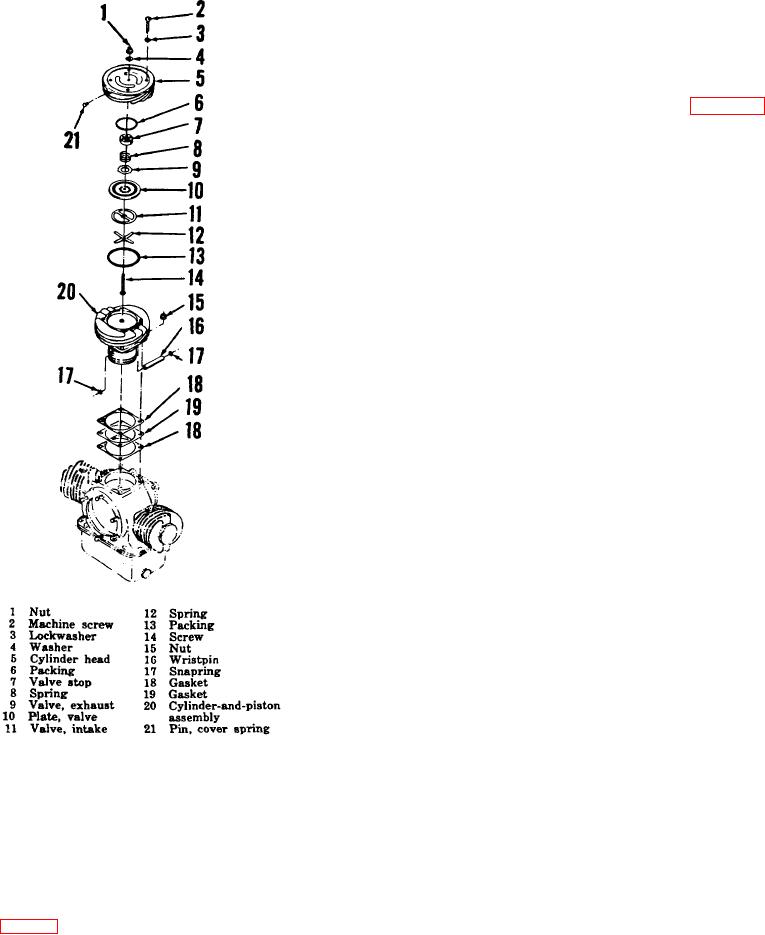

(1) Remove breather assembly (para 3-11c).

(2) Remove four machine screws (2) and

lockwashers (3) attaching cylinder

head (5) to cylinder-and-piston

assembly (20).

Remove cylinder

head.

(3) Unscrew and remove nut (1) and

lockwasher (4) from cylinder head.

Pull screw (14) from cylinder head (5)

and remove spring (12), valve (11),

valve plate (10), valve (9), valve spring

(8), and valve stop (7).

(4) Remove packing (6 and 13).

(5) Remove four nuts (15) and carefully

pull cylinder-and-piston assembly (20)

from crankcase.

(6) Remove snapring (17) from each end

of wristpin (16).

(7) Slide wristpin from piston and rod,

releasing piston. Remove piston.

Note.

The

cylinder-and-piston

assembly consists of matched parts.

Keep parts together and separate from

similar

assemblies

of

other

Scribe small marks

inside skirts to identify side of piston

that was toward fan end of crankcase.

Do not use pliers; use driftpin to

remove wristpin (16).

(8) Remove gaskets (18 and 19). Record

thickness of gasket combination and

discard.

Note. The gaskets used between the

cylinder-and-piston assembly and the

crankcase serve as shims to obtain

proper

piston-head-to-valve-seal

Figure 3-4. First stage section, exploded view.

clearance. The number of gaskets used

will vary with each cylinder.

By

are spring loaded to seat against concentric rings of

measuring the thickness of removed

holes which are drilled through the valve plate and

gaskets and adding 0.005 inch for each

coincide with the inlet and outlet ports in the cylinder

new paper gasket to allow for crush at

head.

installation, new gaskets required to

obtain proper clearance can be selected

b.

Maintenance. Overhaul of the first stage

with ease during reassembly.

section (fig. 3-4) is accomplished by replacing the intake

d.

Assembly.

valve spring, intake valve, exhaust valve, valve stop,

(1) Install steel gasket (19) flanked by

cover spring pin, gaskets, wristpin, retaining ring,

cylinder-and-piston assembly, and attaching parts.

20