TM 3-1040-263-34

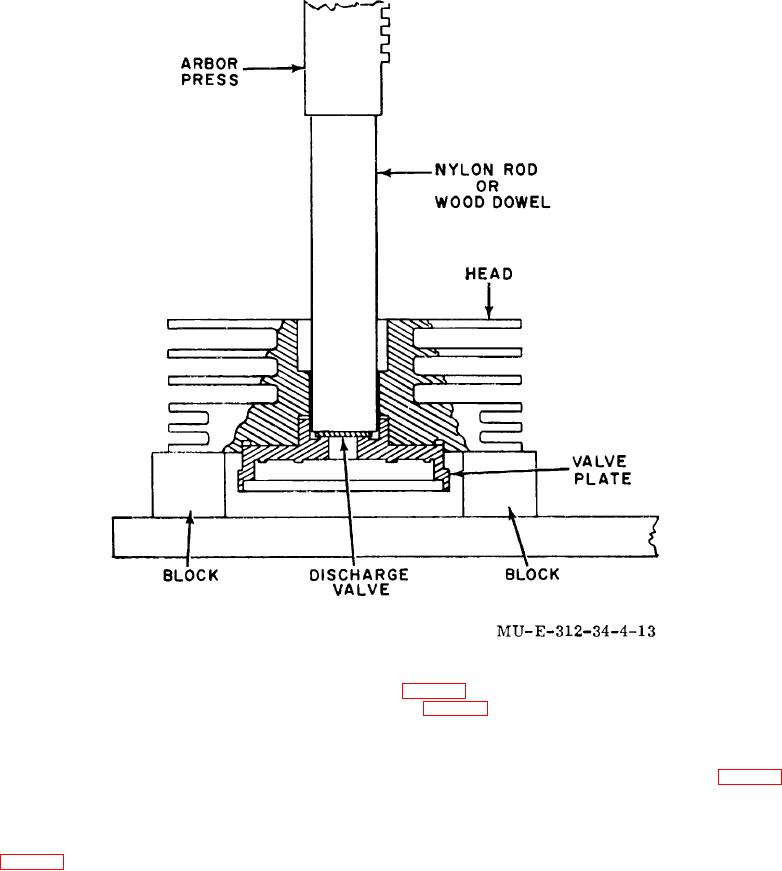

Figure 4-13. Third-stage valve plate removal.

4-12) to obtain discharge valve travel between 0.017 and

fig. 4-12) on the cylinder. Then, determine measurement

0.021 inch.

(11) Determine measurement B (fig.

(8) Position outlet spring (12) on outlet

(12) Obtain result of B minus D and E dimension

valve (13). Position shims (9, 10, and 11) selected in (7)

F from result to obtain available clearance.

above and valve stop (8) into third-stage head (17).

(13) Add all or part of shims (22, 23, fig. 4-12)

Secure in place using screwlock (7). Torque screwlock

to obtain required head clear between 0.035 and 0.041

(7) to 12.5 pound-feet.

inch.

(9) Position third-stage cylinder and

(14) Disassemble parts used to d third-stage

plunger assembly (25) on crankcase. Rotate crankshaft

head clearance.

(13, fig. 4-16) until the third-stage plunger is at top dead

(15) Lubricate all parts with compound prior to

center while seated on the keystone assembly plunger

assembly.

interface surface. Determine measurement F (fig. 4-

14).

(10) Position the third-stage head gasket (20,

4-22