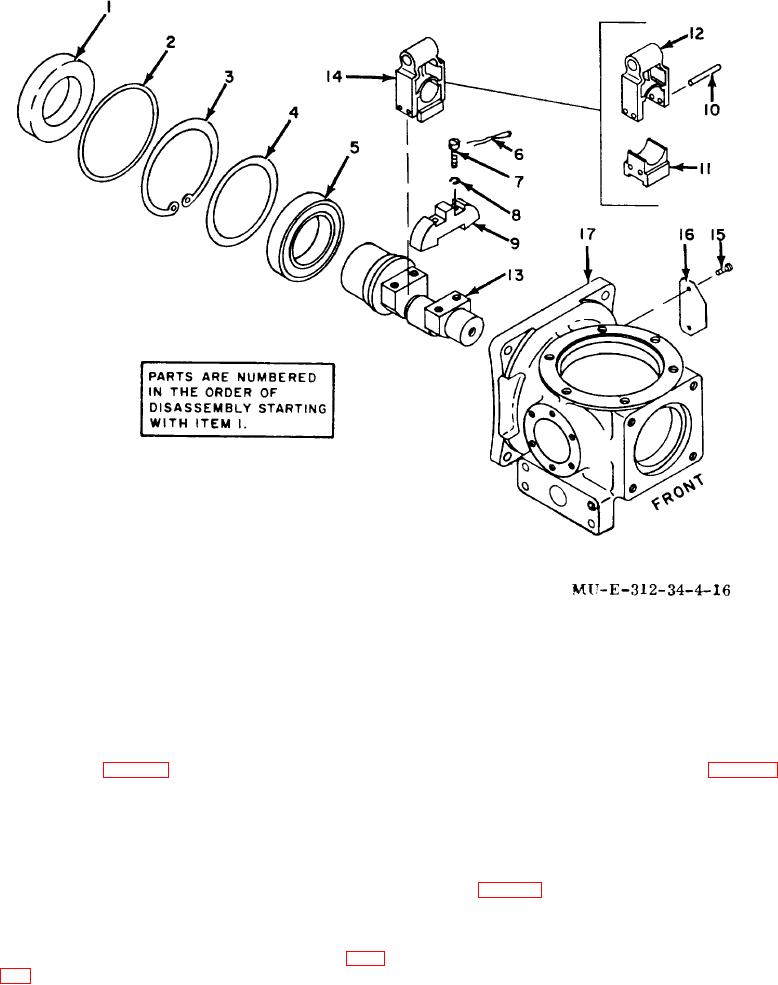

TM 3-1040-263-34

1

Seal

7

Screw

13

Crankshaft

2

Preformed packing

8

Lockwasher

14

Keystone assembly

3

Retaining ring

9

Counterweight

15

Drive screw

4

Spacer

10

Roll pin

16

Nameplate

5

Bearing

11

Wedge

17

Figure 4-16. Keystone and crankshaft exploded view.

crankcase (17, fig. 4-16) and crankshaft (13) passages.

g. Inspect keystone fork (12, fig. 4-16) and

wedge (11) for permanent marks indicating that

components are matched parts. Keep matched parts

b. Clean all metallic parts except the rear

together.

bearing (5) in drycleaning solvent.

h. Reassemble the keystone assembly (14),

c. Apply compressor lubricating oil to cleaned

and measure the diameter tolerances of the keystone

parts to prevent rusting.

d. Inspect all parts for wear or damage.

bores (para 1-4c).

e. Inspect all threads for damage.

4-35. Reassembly

NOTE

f.

Check crankshaft diameter tolerance (para

Fork and wedge are matched parts and are absolutely

not interchangeable with similar parts.

4-26