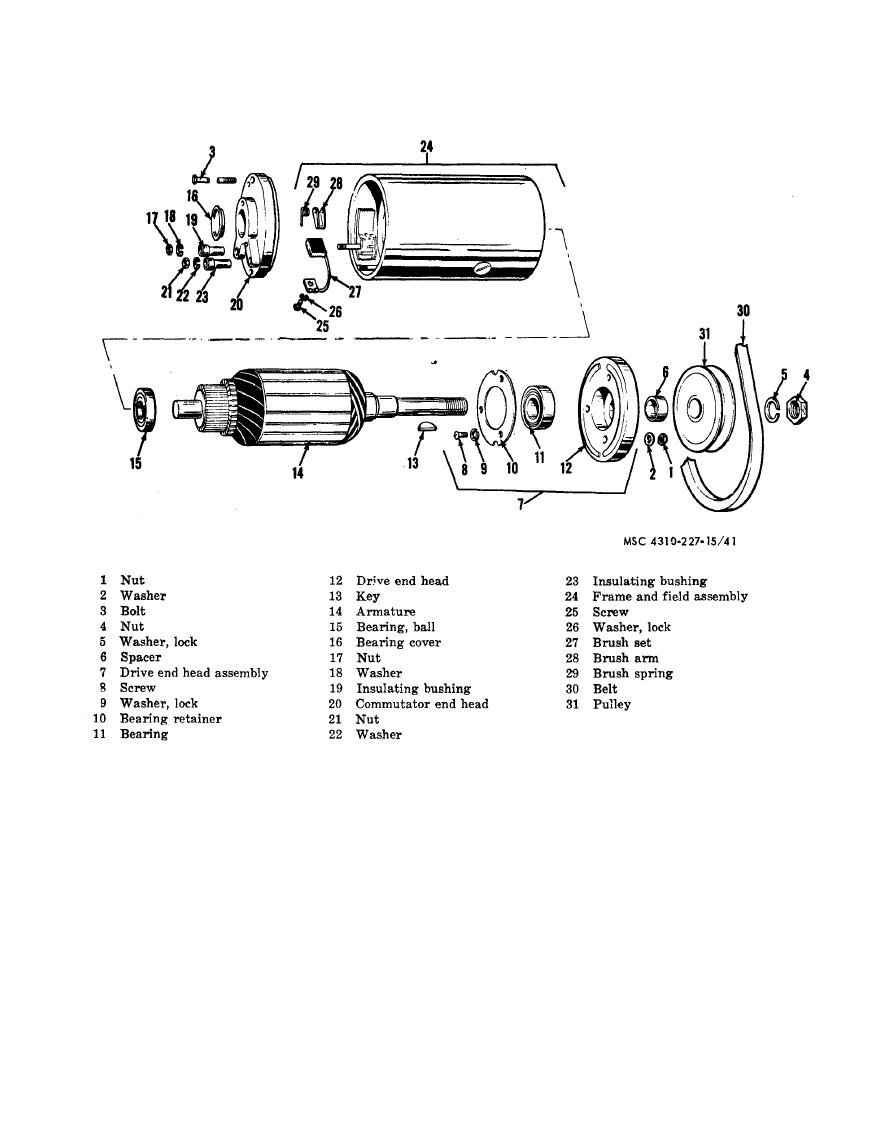

TM 5-4310-227-15

(3) Inspect the drive end frame and the

(7)

Inspect the bearing retainer for

f i e l d winding frame for cracks or

cracks, breaks, or excessive wear. Re-

breaks. Replace if defective.

place if defective.

(8) Clean the armature with a clean cloth

(4) Inspect the ball bearings for free ro-

dampened with an approved cleaning

tation. Replace if defective.

solvent and dry with low-pressure,

(5) Inspect the brushes for cracks, chips,

compressed air. Inspect the commuta-

or breaks. Replace brushes if worn to

tor for rough spots, scoring, pitting,

one-half their original length of sev-

burned, or out-of-round condition. If

en-eights inch.

the commutator is worn, burned, or

(6) Inspect the brush springs for proper

rough, place the armature in a lathe

tension

o r distortion. Minimum

and take light cuts on the commutator

spring tension is 28 ounces. Replace a

until the condition is corrected. Under-

weakened or distorted brush spring.

cut the mica to a depth of 1/32 to

4-14