TM 5-4310-227-15

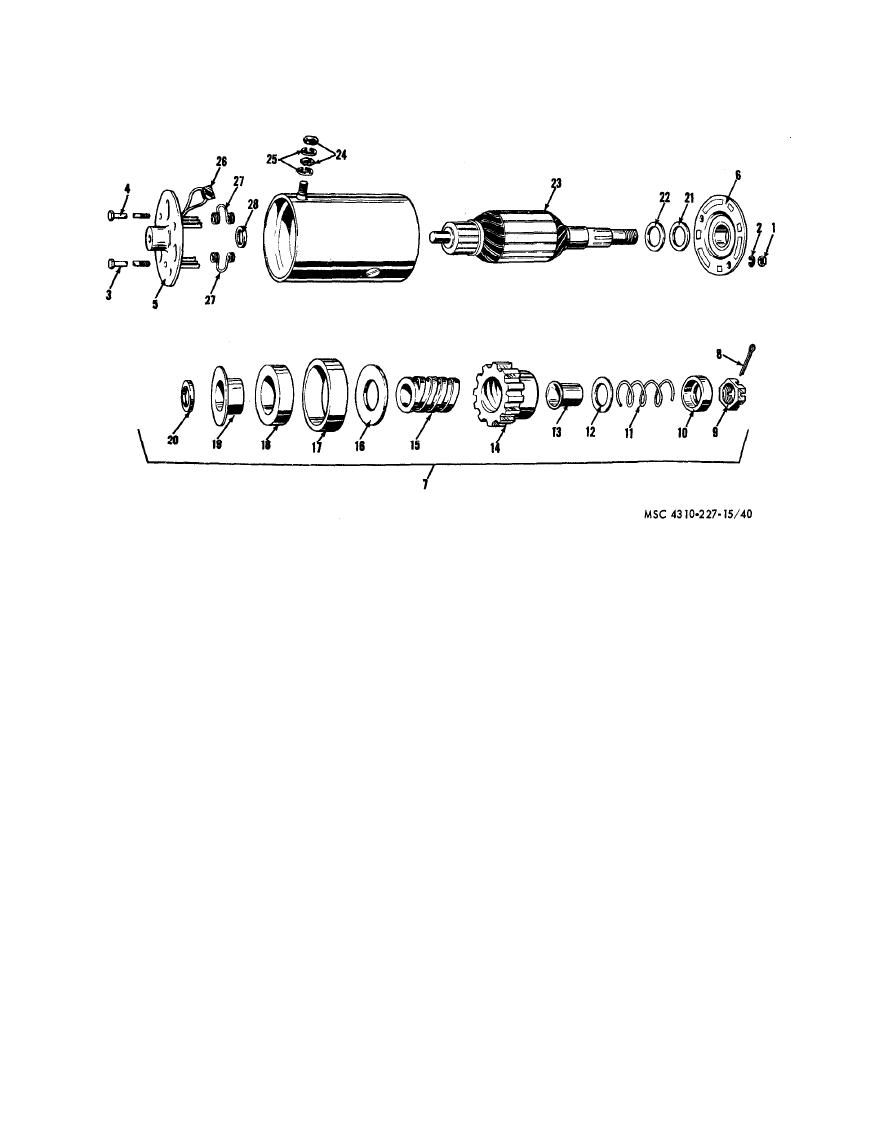

21 Washer, thrust

11 Spring

1

Nut

22 Washer, thrust

2

Washer, lock

12 Pinion washer

23 Armature

13 Sleeve

3

Bolt

24 Nut

14 Pinion

4

Bolt

25 Washer, lock

Commutator and head assemibly 15 Shaft

5

26 Brush

16 Washer, thrust

6

Drive end head assembly

27 Spring

17 Cup, cushion

7

Drive assembly

28 Washer, thrust

18 Cushion

Pin, cotter

8

19 Washer, thrust cup

9

Nut

20 Spacer

10

Pinion stop

(5) Test the armature for grounds with a

(4) Test the armature for open circuits

test lamp circuit. Test Between the

with a growler. Position the armature

armature shaft or core and one of the

o n the growler and energize the

commutator bars. Repeat the test at

growler. With the test probes connect-

t w o or more locations around the

ed to an AC voltmeter, select a pair

commutator to preclude the possibility

o f commutator bars which give a

of testing from an isolated bar. If

readable indication on the voltmeter.

t h e lamps light, the armature is

Maintaining this relation between the

grounded. Replace a defective arma-

test probe position the growler, turn

ture.

the armature one slot at a time until

(6) Inspect the field windings housing,

all coils are tested. The voltmeter

e n d b e l l , drive housing, and pole

readings should be nearly uniform. If

shoes for cracks, breaks, or other dam-

the armature has been proven free of

age. Replace as necessary.

shorts (see (3) above), a low or zero

(7) Inspect a l l hardware for cracks,

reading indicates an open circuit, Re-

breaks, or damaged threads. Replace

defective parts.

place a defective armature.

4-11