ing or pressing the gear on the shaft

having over .005 inch clearance be-

tween shaft and arm. Inspect the

does not cause the shaft to bump the

rocker arm brackets for cracks or

expansion plug at the rear end, forc-

ing it out of position and causing an

other damage.

(7) Inspect push rods for bends or twists

oil leak.

and examine the ball and cup ends for

Install any tappets (16) which were

(2)

excessive wear. Replace rods that are

removed for examination or replace-

faulty or excessively worn.

ment. Tappets can be removed from

(8) Check the clearance of the camshaft

the top of the block without pulling

journal in the bearing hole or bushing.

the camshaft, by means of a mag-

If the clearance equals or exceeds the

n e t i z e d rod.

wear limits given in paragraph 94,

(3)

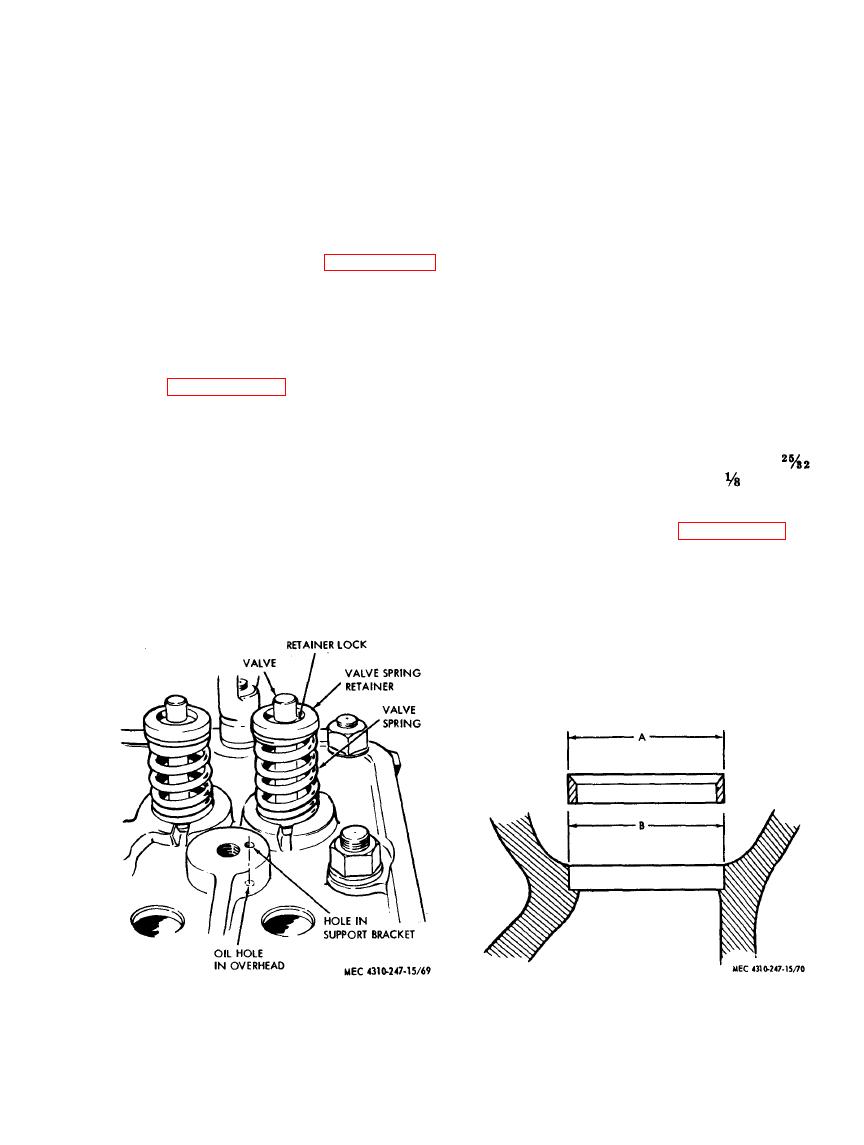

Refer to figure 69. First coat the valve

check the diameter of the camshaft

stems with a light film of engine oil,

journals. If the wear is excessive, the

then reassemble the valves (24, fig.

camshaft must be replaced.

66) and springs (20) in the head with

(9) Check the outside diameter of all tap-

the retainers (19) and retainer locks

pets (16) with micrometer and re-

(18). The close-wound coils of the

place if excessively worn. Refer to

valve spring should contact the cylin-

der head.

scores or damage to contact face. Two

(4)

Replace worn guides (22) by pressing

or three small pits is acceptable; re-

in new guides from the combustion

place if excessively pitted.

side to the correct depth below the cyl-

(10) Examine the camshaft thrust plate

inder head contact surface (2

(32) for scoring and wear. Replace

inch for intake guides, 3

inch for

if unsatisfactory.

e x h a u s t guides).

(5)

Ream new valve stem guides to sise if

c. Reassembly and Installation. Reassemble

necessary. Refer to paragraph 94.

and install the rocker arm and camshaft parts

Caution: Ferrox coated guides are

of the engine as shown in figure 66.

now used on some models. These are

(1) Assemble the cam gear (29) to the

pre-reamed and they do not require

camshaft (35) by holding the cam-

further reaming after installation.

shaft forward so that the act of driv-

(6)

When replacing valve seat inserts

with new inserts, clean and counter-

bore for .010 inch larger insert. Limits

are 1.6888/1.687 inch for inside diam-

eter of counterbore (B), and 1.692/

Figure 69. Valve reassembly.

Figure 70. Valve seat insert.

AGO 8166A

91