to the torque specified. Use lockwires, cotter

pins, or lockwashers as required, to prevent

nuts and screws from becoming loose.

(1) Assemble the pistons (45) on the con-

necting rods (36) at room tempera-

ture (approx 75 F.). Tap the pins

(44) into place through the rod bush-

ing (41). The piston pin hole in the

connecting rod must be parallel to and

in plane with the large bore in the

bearing end of the rod. The snap rings

(43) must be firmly seated in the

grooves.

(2) Install piston rings (46, 47, 48, and

49). Grip the connecting rod (36) in

a vise with leadlined jaws to hold the

piston (45) firmly, and roll each ring

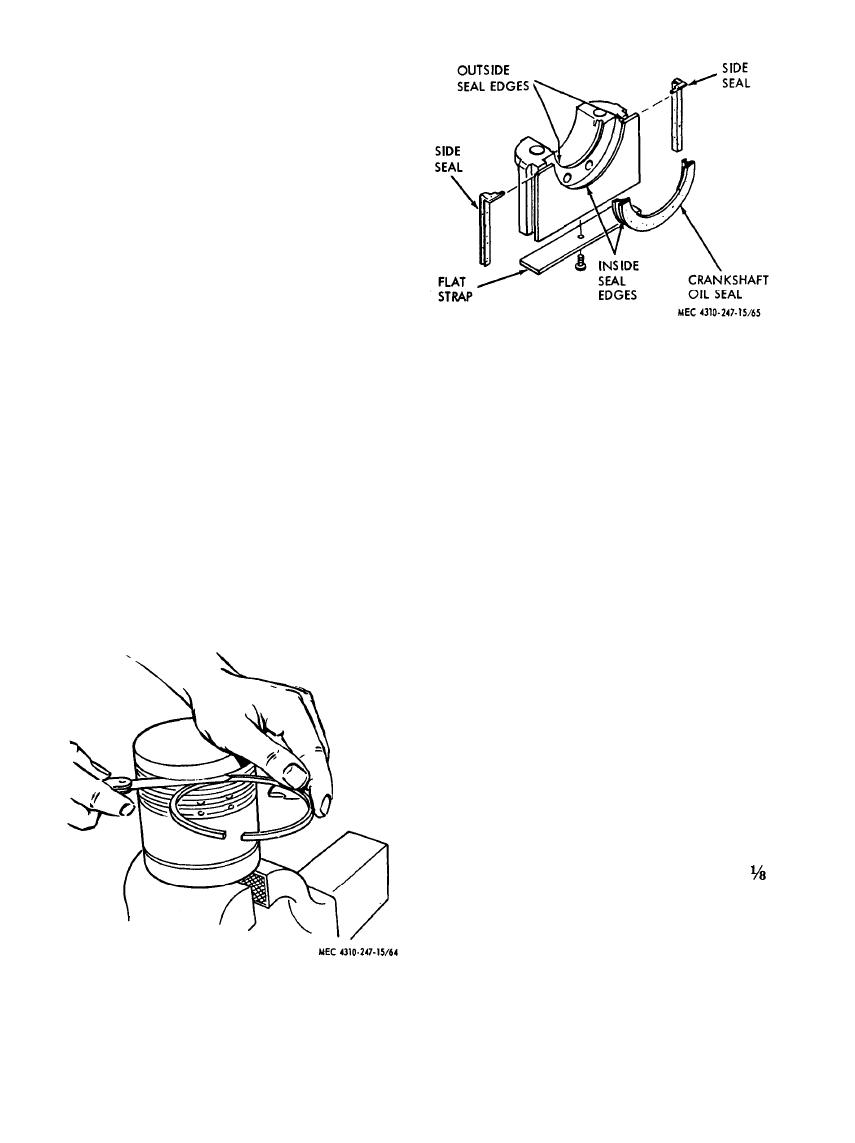

Figure 65. Filler block and seal reassembly.

in its groove to make sure there are no

seal lip to make sure sealing surface

burrs or other material to impede the

is clean, smooth, and free from nicks.

free action of the ring in the groove.

Apply a thin coating of seal lubricant

Start with the lowest ring (49).

to lip surface before installing, and

Caution: Do not expand rings more

break edge slightly on both the cap

than necessary to fit over piston. Ex-

and the block, to prevent cutting the

cessive expansion of a ring may cause

seal during installation. Coat outside

distortion which can not be detected

seal edge (contacting the groove) with

by visual inspection. Tapered piston

cement.

rings must be installed with top side

Note. This oil seal can be installed without

up.

removing the crankshaft. In this case, use

(3) Refer to figure 65 and install crank-

only light grease in the seal groove in the

shaft oil seals on engine block and

cylinder block when sliding the seal in place.

Apply pressure to the seal so that it will hug

bearing cap (22, fig. 57). Check oil

the crankshaft. This also helps to move it

into place.

(4) Slide the side seals (fig. 65) into the

filler grooves without oil. Then coat

the outside edge lightly with an oily

finger to help slide in the block with-

out stretching.

(5) Apply a light coat of cement to the tab

end side seal surfaces that contact

both the block and filler block. Allow

it to become tacky before assembling.

Caution: Do not use too much

cement. Make sure no cement gets on

lip of seal.

(6) Bolt a flat strap (fig. 65) (approx

by 1 by 6 in.) to bearing cap, using

the same hole that was used for puller.

This strap will hold the side seals in

place during assembly to block. After

assembly, remove strap. The side

slabs should not project more than

Figure

64.

Ring

groove

clearance.

AGO 8166A

88