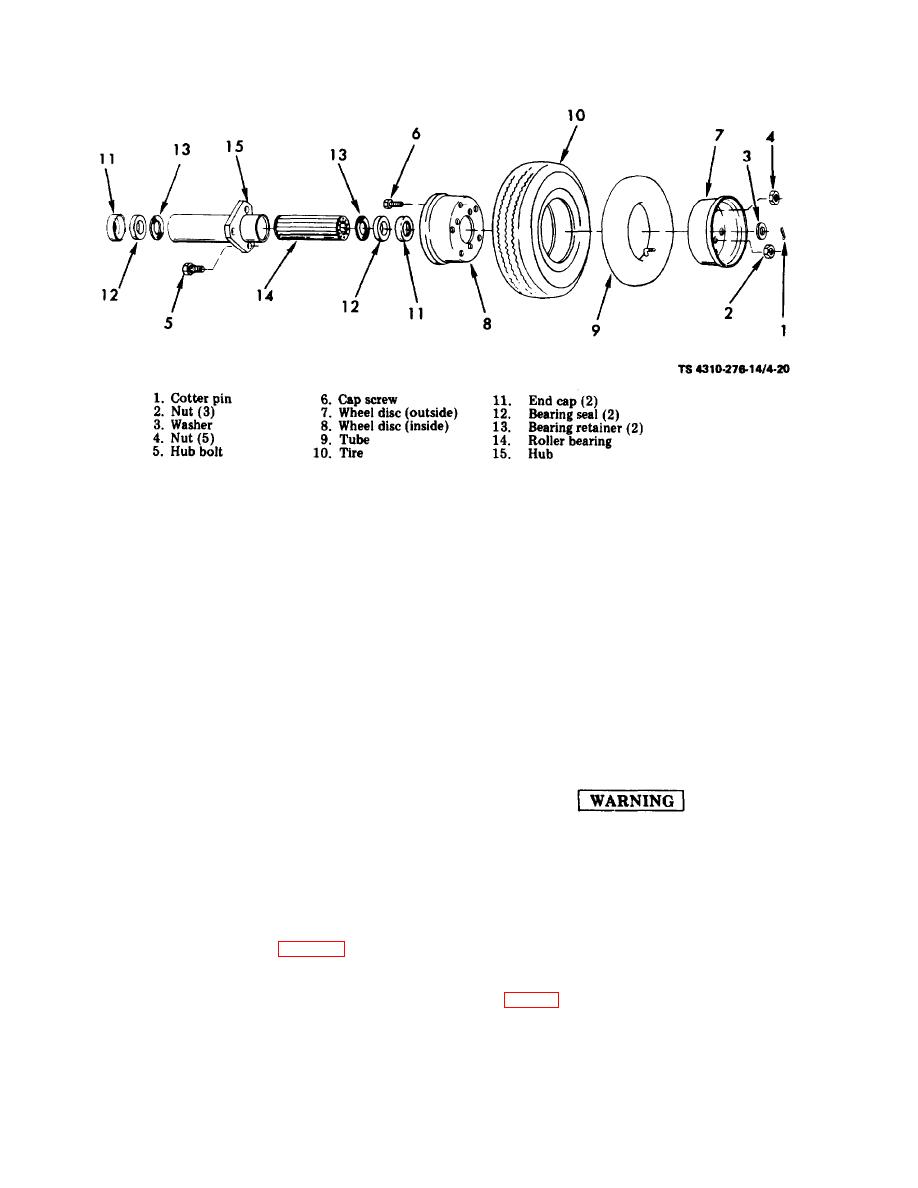

TM 5-4310-276-14

(2) Assemble hubs (15), bearings (14), bearing

(4) Disassemble the wheel disc front half (7),

retainers (13), bearing seals (12), and end cape (11).

wheel disc rear half (8), tube (9) and tire (10).

(3) Install the tube (9), tire (10), wheel disc

(5) Disassemble end caps (11), bearing seals

rear bald (8), and wheel disc front half (7).

(12), bearing retainers (13), roller bearings (14) and

(4) Install capscrews (6), hub bolts (5), nuts

hubs (15).

(4), washers (3), nuts (2) and cotter pins (1).

(6) Remove axle.

(5) Service the tires to 25 psi (1.766 kg/sq cm).

(7) Inspect axle for cracks or bends. Replace

(6) Remove the blocking and lower the jack.

axle is damaged beyond usage.

b. Installation

(1) Install axle on handtruck.

Section XI. MAINTENANCE OF WHEELS AND TIRES

hub (15).

4-23. General.

b. Cleaning and Inspection.

The compressor assembly is mounted on a har-

ndtruck, equipped with two rubber tired wheels

with roller bearings mounted on the truck axle hub.

Drycleaning solvent, P-D-680, used to

clean parts is potentially dangerous to

4-24. Wheels and Tires

personnel and property. Avoid re-

a. Removal.

peated and prolonged skin contact.

(1) Jack up the axle end of the compressor as-

Do not use near open flame or exces-

sembly and block securely.

sive heat. Flash point of solvent is

(2) Release air from tires.

100F (38C).

(3) Remove cotter pins (1, fig. 4-20), nuts (2),

washers (3), nuts (4), hub bolts (5) and capscrews

(1) Wash all parts with cleaning csolvent,

(6).

item 5, App. D, and dry thoroughly.

(4) Disassemble the wheel disc front half (7),

(2) Inspect bearings, seals and retainers for

wheel disc rear half (8), tube (9) and tire (10).

b r e a k s or excessive wear. Service bearings or re-

(5) Disassemble end caps (11), bearing seals

(12), bearing retainers (13), roller bearings (14) and

4-36