TM 5-4310-276-14

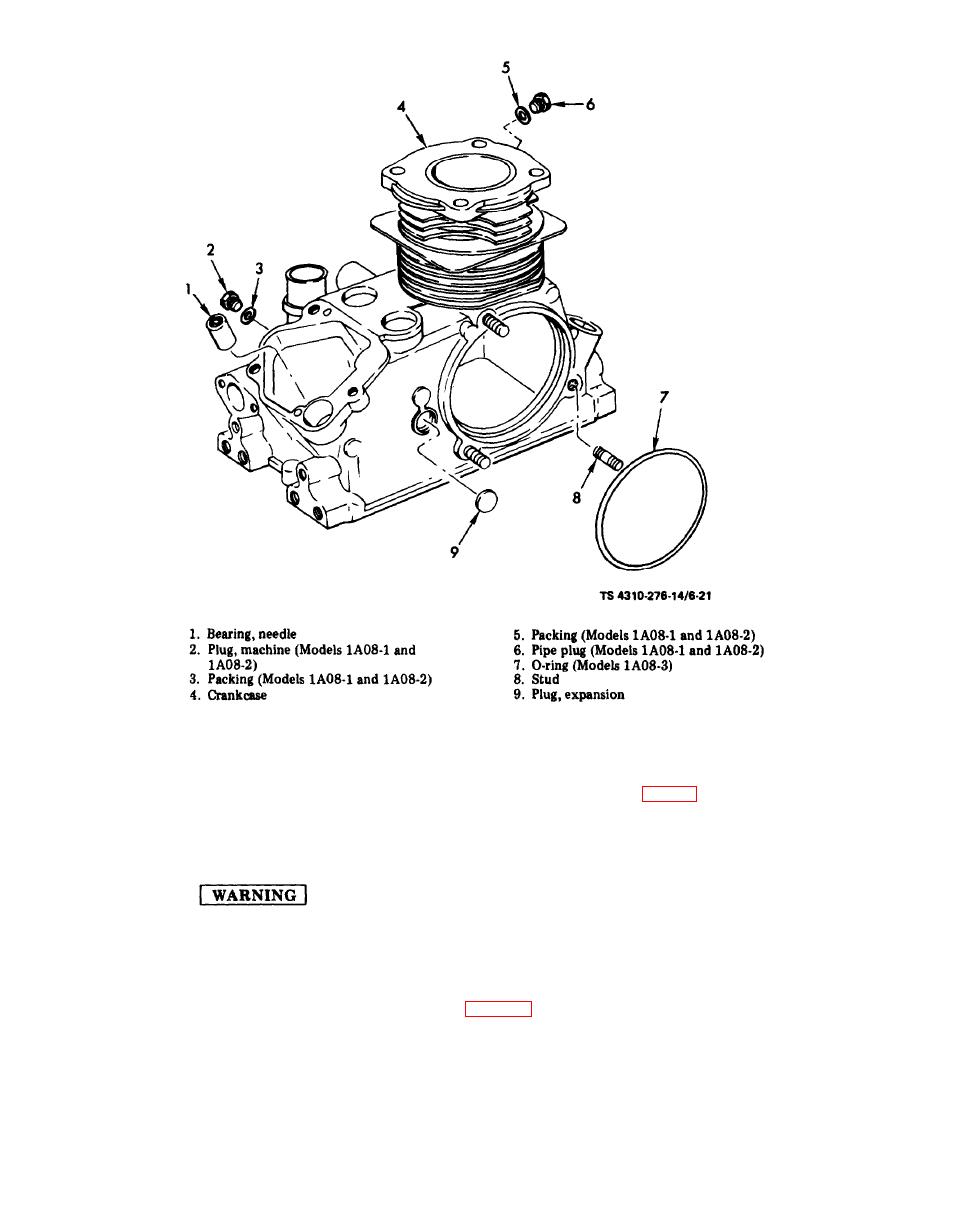

(19) R e m o v e plug (2), packing (3), plug (6),

and packing (5) from Models 1A08-1 and 1A08-2.

cleaning solvent, item 5, App. D.

(20) Remove O-ring (7) from Model 1A08-3.

(21) Remove studs (8) and expansion plug (9).

stripped or damaged threads. Inspect oil seal for ser-

b. Cleaning, Inspection, and Repair.

viceability and any visible damage. Inspect oil pan

and bearing cap mating surfaces for warpage,

scratches, nicks, or other damage. Inspect cooling

fins for breaks or bent fins. Inspect engine mount-

ing pads for serviceability, threaded inserts prop-

Drycleaning solvent, P-D-680, used to

erly installed and no damage to the threads. Inspect

clean parts is potentially dangerous to

cylinder wall for excessive wear, scoring, corrosion

personnel and property. Avoid re-

or pitting. Inspect camshaft and valve tappet bear-

peated and prolonged skin contact.

ing surfaces for wear, pit ting or scoring. Refer to

Do not use near open flame or exces-

sive heat.

6-26