TM 5-4310-276-14

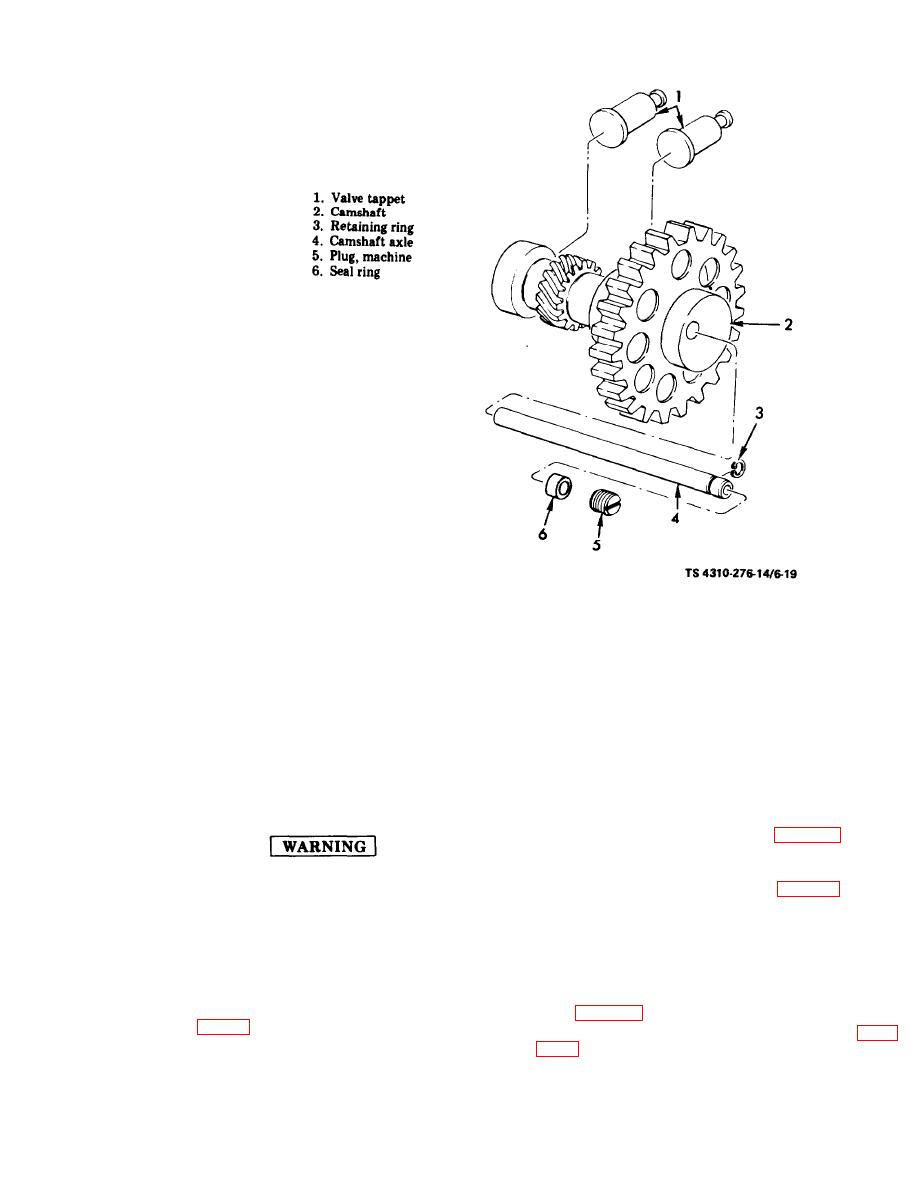

(2) Inspect the camshaft for excessively worn

(4) Insert one of the oil pan mounting screws

lobes, chipped or broken gear teeth, cracks, worn or

into the threaded end of the camshaft axle (4) and

scored bearing surfaces or evidence of overheating.

pull the axle out with a pair of pliers.

(5) Remove retaining ring (3) from axle.

(3) Inspect axle for cracks, breaks, scoring, ex-

(6) Remove camshaft (2) and valve tappets

cessive wear or evidence of overheating.

(1).

(4) Inspect valve tappets for excessive wear,

b. Cleaning, Inspection, and Repair.

freedom of operation in crankcase, or evidence of

overheating.

(6) Replace any damaged or defective part.

c. Reassembly and Installation.

Drycleaning solvent, P-D-680, used to

clean parts is potentially dangerous to

stall the camshaft (2). Install the retaining ring (3)

personnel and property. Avoid re-

on the camshaft axle (4) and install the axle. Re-

peated and prolonged skin contact.

move the oil pan retaining screw from the axle. In-

Do not use near open flame or exces-

stall a new oil seal (6) and install the machine plug

sive heat.

(5).

(2) Install the oil pan and service the crank-

(1) Clean all parts with drycleaning solvent,

case (para. 6-2).

item 5, App. D.

6-23