TM 5-4310-277-14

clean parts is potentially dangerous to

personnel and property. Avoid re-

peated and prolonged skin contact.

Do not use near open flame or exces-

sive heat. Flash point of solvent is

100oF. (38C.)-138oF. (59C. ).

(1) Clean the parts with cleaning solvent, Fed-

eral Specification P-D-680, and dry thoroughly.

(2) Inspect valve parts for cracks, breaks,

damaged threads, wear or other damage. Replace

worn or defective parts.

c. Assembly and Installation. Reassemble

and install the check valve as follows:

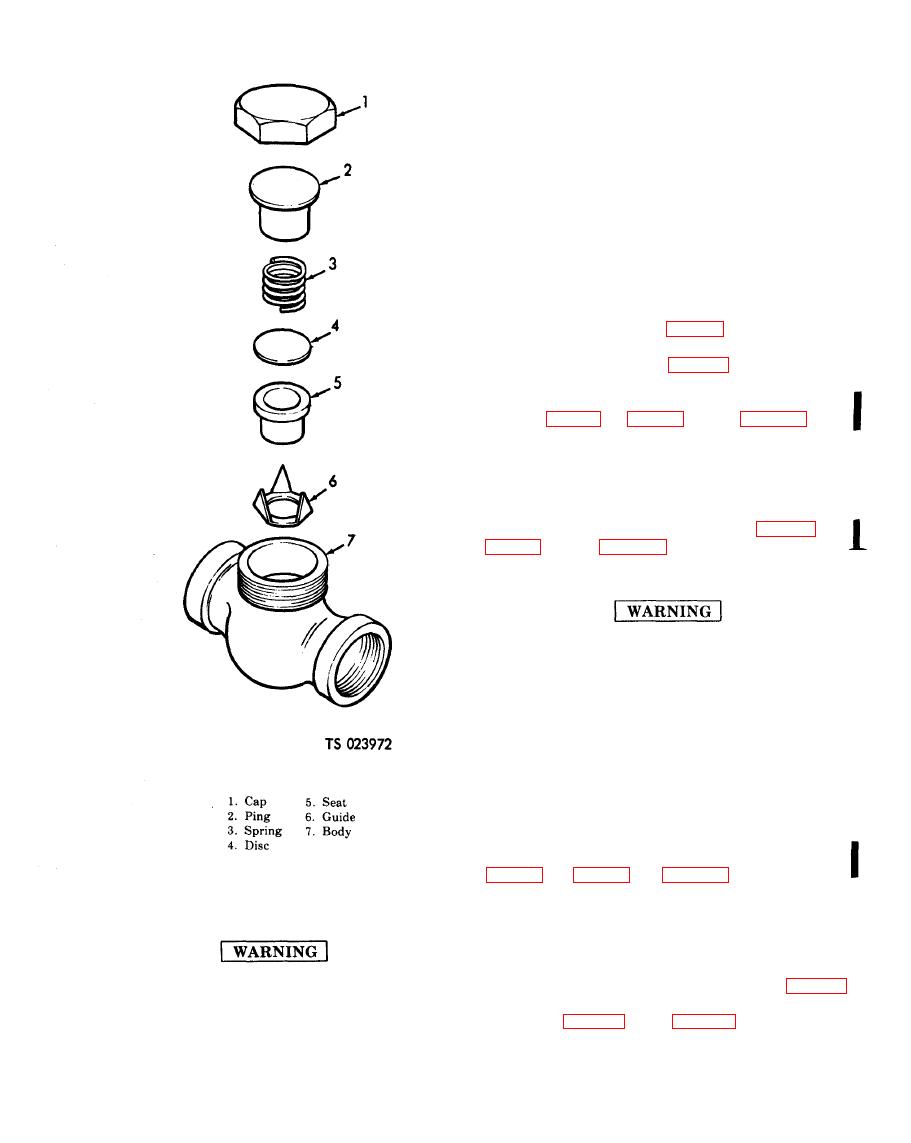

(1) Install guide (6, fig. 4-27), seat (5), disc (4),

spring (3), ping (2), and cap (1) on body (7).

(2) Install gasket (4 fig. 4-26), valve assembly

(3), O-ring (2), and plug (1) on body (5).

d.1. For model (HGR5-8M-6) install the pressure

gage (2, fig. 4-24)9, fig. 4-25, or 13, fig. 4-25.1).

4-33. Pressure Gage

a. Removal.

(1) Stop the air compressor, and release all air

from the compressor by opening the draincock.

(2) Remove the pressure gage (2, fig. 4-24, 9,

b. Cleaning and Inspection.

Dry cleaning solvent, P-D-680, used to

clean parts is potentially dangerous to

personnel and property. Avoid re-

peated and prolonged skin contact.

Do not use near open flame or exces-

sive heat. Flash point of solvent is

100F. (38C. ) - 138F. (59oC. ).

Clean gage with a cloth dampened with clean-

ing solvent, Federal Specification P-D-680, and dry

thoroughly. Check for cracks, dents, breaks, or other

damage. Replace gage if damaged or broken.

c. Installation. Install the pressure gage (2,

1, serial numbers 13655 through 13745).

4-34. Globe Valve and Inflator Gage

b. Cleaning and Inspection.

a. Removal and Disassembly.

(1) Stop the air compressor, and release all air

from the air receiver by opening the draincock.

Dry cleaning solvent, P-D-680, used to

(2) Remove the air hose assembly (2, fig. 4-25)

from the globe valve if attached. Remove the globe

valve (3, fig. 4-24 or 5, fig. 4-25) from the air

receiver.

Change 1