28. VALVE ASSEMBLIES. (See fig. 10) When any

valve assembly is removed, always install a new

valve gasket. Be sure to replace a valve assembly in

its original position.

29. CRANKCASE HAND HOLE PLATE. When hand

hole plate (See fig.9) is removed for any reason,

always install a new hand hole gasket (22).

30. CRANKSHAFT BEARING ASSEMBLIES. (See

fig. 9) The bearing assemblies are pressed onto

the crankshaft up against a shoulder. Be sure to

press bearing cone and roller and bearing cup until

positive stop is reached.

(See fig.

9)

3 1 . P I S T O N C O N N E C T I N G R O D S

When installing a new piston connecting rod, be sure

that both parts of the new rod are used. Both parts of

the old rod must be discarded.

32. PISTON RINGS. (See fig. 9) Piston rings

are received in sets and upper and lower rings are

identified in the sets.

33. TEST PROCEDURE

Table 3 indicates the minimum performance

standards that the equipment must meet. To make the

test, perform the following steps.

a.

b.

c.

d.

e.

f.

Place toggle switch (2,fig. 6) to off (down)

position.

Remove air hose assembly (fig. 1) from

g l o b e v a l v e a s s e m b l y ( 1 5 , f i g . 8 ).

Open globe valve assembly (CCW) until pressure

gage

indicates 0 psi, then close valve as-

sembly.

Reconnect air hose assembly and open globe

valve assembly.

Place toggle switch to on (up) position and

check pumping time according to table 3. If

cut-out pressure is incorrect, adjust accord-

ing to paragraph 34.

Operate inflator gage assembly to lower air

pressure until compressor starts.

If cut-in

pressure is incorrect, adjust according to

paragraph 34.

Table 3. Minimum Pumping Time Requirements

PRESSURE

PUMPING TIME

0 to 100 psi

12 minutes

0 to 125 psi

15 minutes

0 to 150 psi

18 minutes

0 to 175 psi

21 minutes

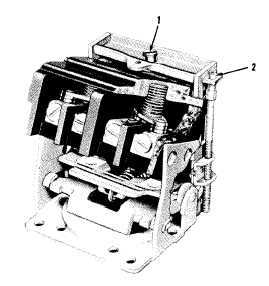

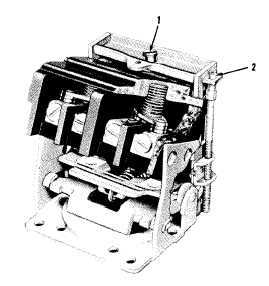

34. ADJUSTMENT

a. To raise cut-in and cut-out pressure, turn

screw (1, figure 5) on pressure switch assem-

bly clockwise.

CAUTION

Do not turn screw (2) further that it

will turn easily.

1. PRESSURE ADJUSTMENT SCREW

2. DIFFERENTIAL ADJUSTMENT SCREW

Figure 5. Pressure Switch Assembly Adjustments

b. To lower differential (difference between cut-

in and cut-out pressure), turn screw (2) coun-

terclockwise.

c. To increase differential and maintain same

cut-out pressure, simultaneously turn screw

(2) clockwise and turn screw (1) counterclock-

wise.

NOTE

If differential is increased by turning

only screw (2) clockwise, the cut-in

pressure changes only slightly and the

cut-out pressure rises.

35. TROUBLESHOOTING

Table 4 lists troubles that may occur during in-

stallation, operation and test. One or more remedial

steps are indicated for each of the troubles.

5

307-967 O - 68 - 2