TM 5-4310-335-14

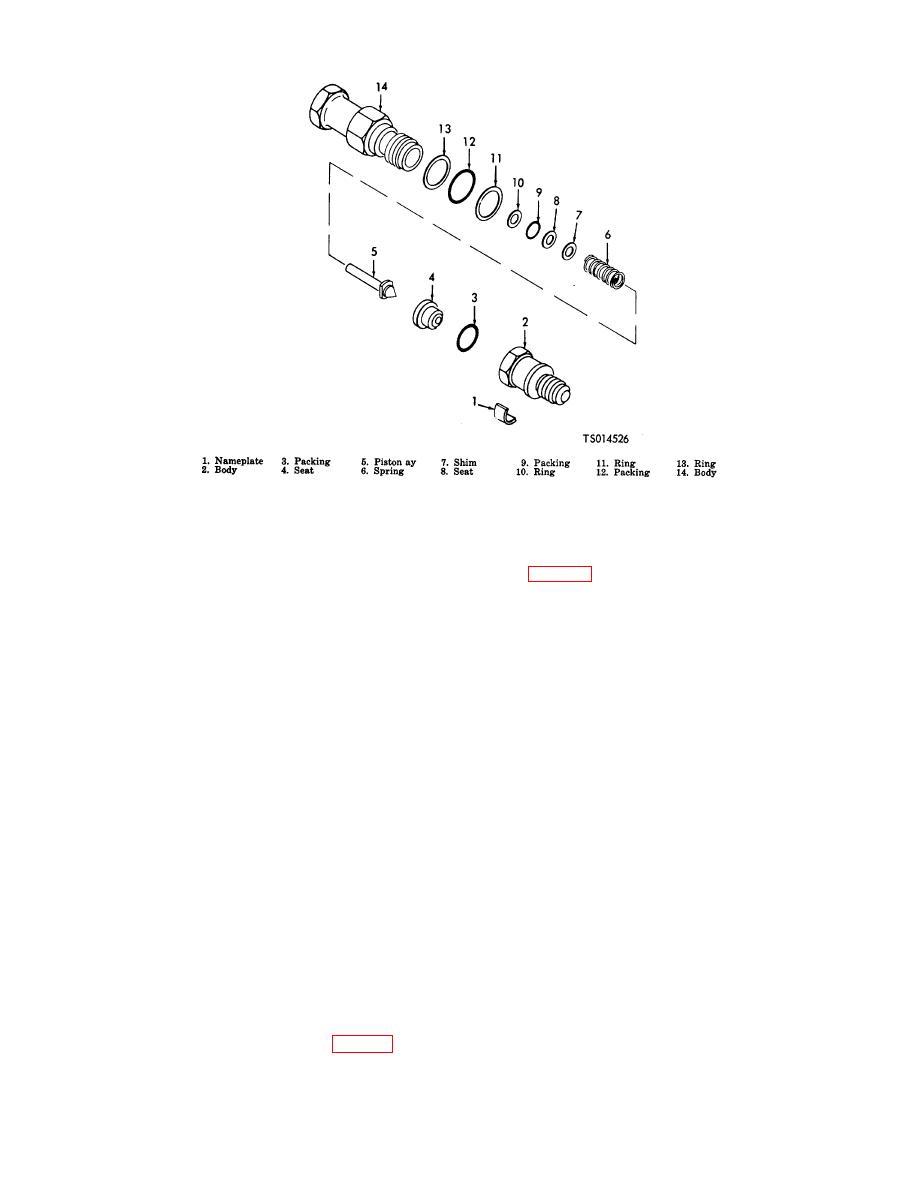

Figure 6-9. Back Pressure Valve Assembly

shim (6), spring retainer (7) and helical spring (8).

(b)

Remove plain hexagon nuts (9), lock- washers (10), flatwasher (11), machine screws (12),

flatwashers (13), shims (14), control valve (15, fig. 6-12) and bracket (16).

(c)

Remove nylon pan head screw (17), setscrew (18), actuator knob (19), stop nut (20), jam

nut (21) and cap (22) leaving body (23).

NOTE

Do not disassemble cap (22) from body (23) unless replacement of either part is

necessary.

WARNING

Dry cleaning solvent, P-D-680, used to clean parts is potentially dangerous to

personnel and property. Do not use near open flame or excessive heat. Flash

point of solvent is 100 - 138 . (38 to 59 ).

F

F

C

C

b. Cleaning. Clean metallic parts of the valves using cleaning solvent, Fed. Spec. P-D-680, and dry

thoroughly using filtered compressed air.

c. Inspection.

(1) Inspect packing for wear and deterioration.

(2) Inspect back up rings, washers, brackets, clamp, and spring for warpage and

corrosion.

(3) Inspect timer gear for cracked, chipped or broken teeth.

(4) Repair any damage or replace parts which obstruct moving parts or could cause

damage to the equipment.

d. Repair.

(1) Replace preformed packing.

(2) Replace damaged, defective or missing parts.

e. Assembly. Detailed reassembly procedures and testing requirements are listed where warranted.

(1) Back Pressure Valve. (fig. 6-9).

(a) Assemble the valve in the reverse order of the disassembly procedure, observing the

following additional instructions.

6-17