CHAPTER 4

ORGANIZATIONAL MAINTENANCE INSTRUCTIONS

Section I. SERVICE UPON RECEIPT OF MATERIEL

and general accessibility.

Position belt wheel side

4-1. Inspecting and Servicing the Equipment

towards a wall, leaving at least 15 inches for air

circulation to the belt wheel fan.

storage in a new or used condition. In either case, a i pre-

operative check must be made to assure that the

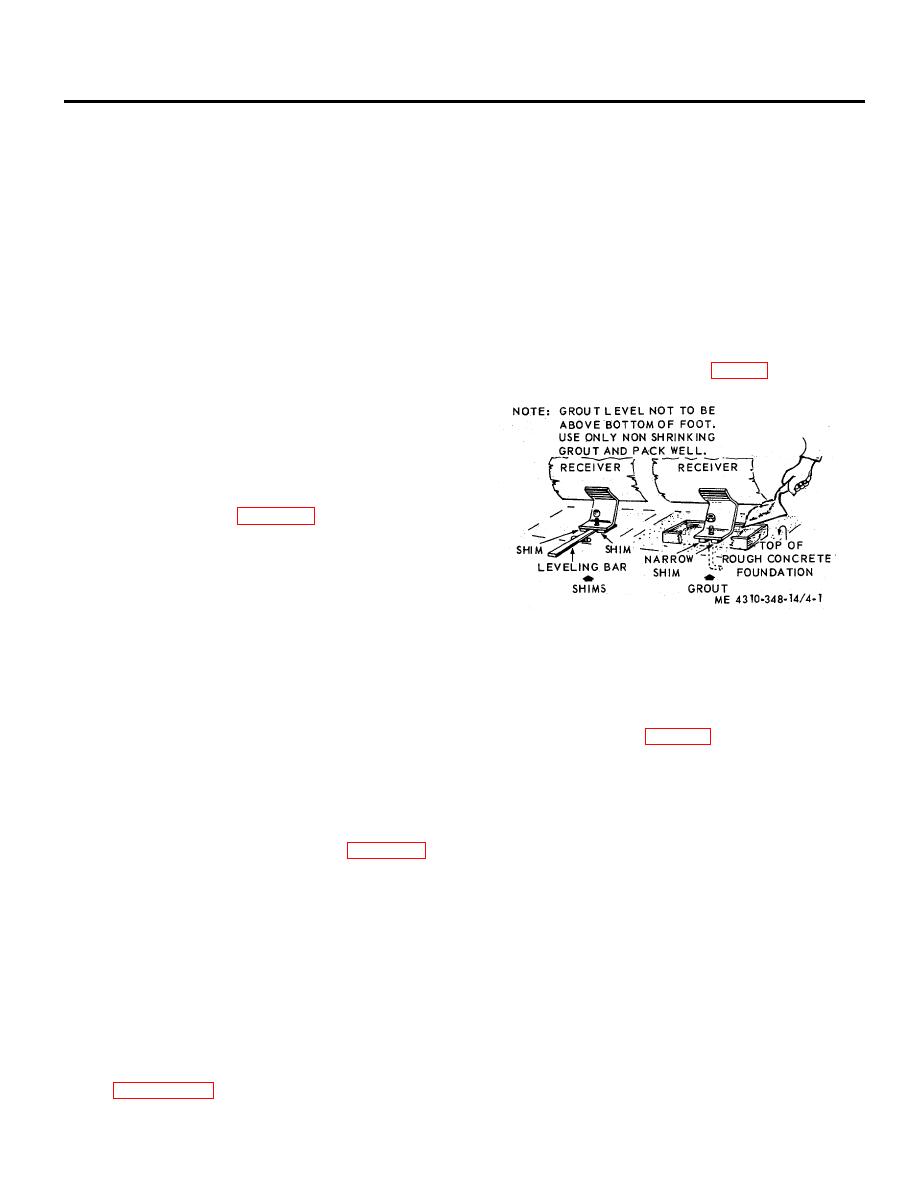

c. Installation. To prevent vibration and insure

equipment and its components are. ready for operation

proper operation, it is important that the unit be level and

without danger to equipment or personnel.

the receiver feet pulled down on shims in such a manner

as to avoid pre-stressing the feet and receiver. Install on

b. Inspecting the Equipment.

base as follows:

(1) Inspect the motor identification plate for

(1) Position feet over bolts, start nuts on bolts.

current and voltage specifications, and compare with the

electric service available. Check that the motor is

(2) Tighten. evenly any three of the nuts, to a

correctly wired. Be particular about checking the wiring

moderate torque, then check the unit for level. If not

and voltage of a dual voltage motor.

level, insert metal shims, or grout (fig. 4-1) under one or

two of the feet to obtain level, and re-tighten the nuts.

(2) Inspect the assembly for any obviously

missing parts, or damages that may have occurred during

transit.

(3) Check for all parts that may have been

removed and packaged separately for shipment.

(4) Inspect the

drive V-belts (a matched pair).

Check the adjustment

compressor drive wheel

through several revolutions by

hand. This will assure

that everything is free and in

working order.

c. Servicing the Equipment. Service the compressor

frame with compressor oil.

Figure 4-1. Leveling the air receiver.

NOTE

(3) Check the distance the unanchored foot is

The motor driving this compressor

elevated above the base, and insert metal shims under

has ball bearings lubricated for life.

this foot, sufficient to provide firm support.

It has no grease fittings, or plugs

(4) After all shims are inserted and the unit is

near the bearings, and requires no

level, tighten nuts on all feet to a moderate (not

lubrication.

excessively tight) torque (table 1-1).

4-2. Installation

d. Power. When the available power supply is equal

a. General The unit may be bolted to any relatively

to that required by motor (para 4-lb. above), and no other

level floor or base. If such a surface is not available, an

electrical equipment is on the circuit, number 8 AWG wire

adequate base must be constructed. Should a concrete

connected to a feeder not more than 100 feet away, will

base be necessary, be certain that bolts are imbedded

carry the load.

correctly to accept the feet of the receiver, and extend at

least one inch above the base. Refer to figure 1-3 for

mounting dimensions.

b. Location.

Choose a clean, relatively cool

location, if possible, and provide ample space for cooling

Section II. REPAIR PARTS, SPECIAL TOOLS, AND EQUIPMENT

4-3. Special Tools and Equipment

4-4. Maintenance Repair Parts

There are no special tools or: equipment required to

Repair parts and equipment are listed and illustrated in

perform maintenance on the air compressor.

the "Repair Parts and Special Tools List" TM 54310-348-

24P.

Section Ill. LUBRICATION INSTRUCTIONS

Refer to Paragraph 3-2 for lubrication instruction for this air compressor.

4-1