TM 5-4310-354-14

b. Cleaning and Inspection.

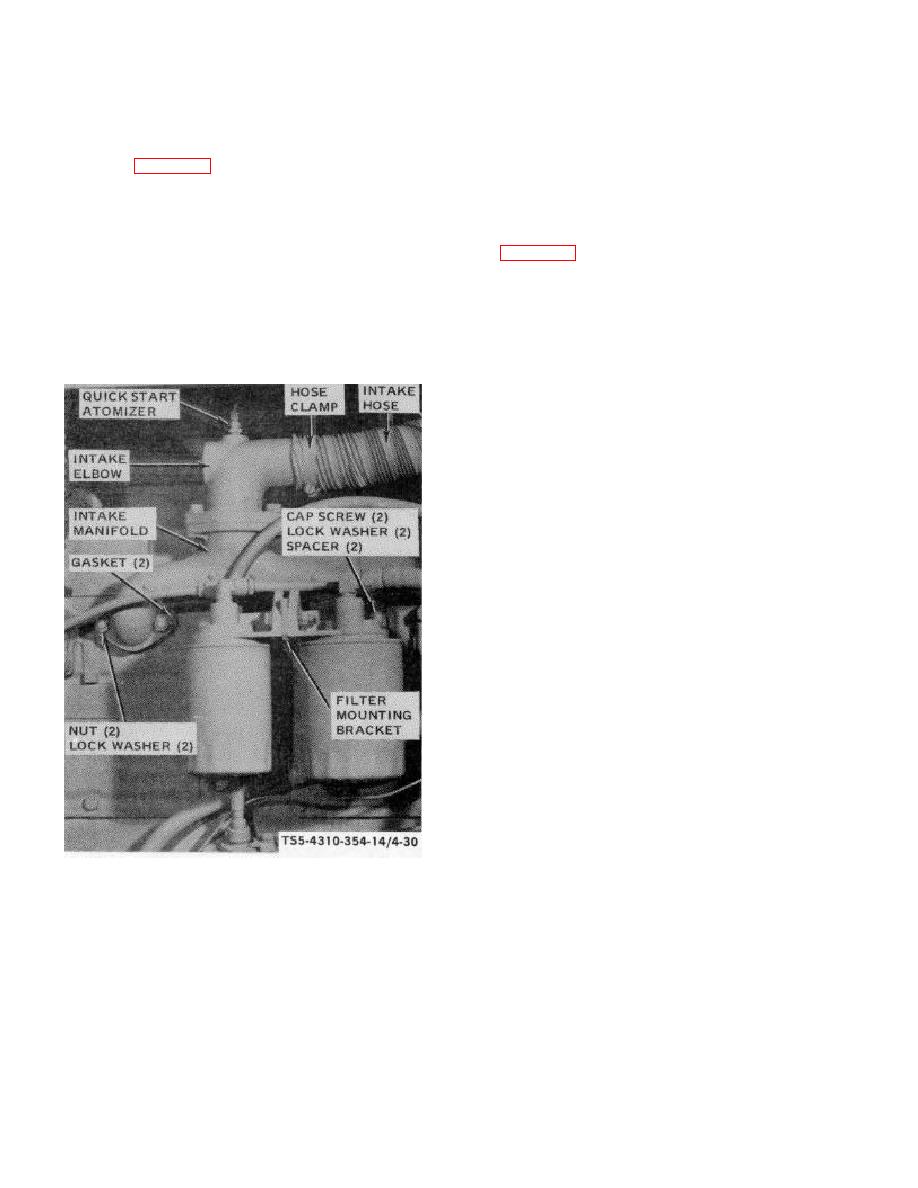

Clean the intake

4-46. Intake Manifold.

manifold with solvent, Federal Specification P-D-680,

a. Removal. Remove the engine intake manifold

Type II. Dry thoroughly. Make certain gasket surfaces

as shown in figure 4-30.

on manifold and cylinder head are clean. Inspect the

manifold for cracks, distortion, breaks, and mounting

hardware for damaged threads.

WARNING

c. Installation. Install the intake manifold as shown

Dry cleaning solvent, P-D-680, used

in figure 4-30.

to

clean

parts

is

potentially

dangerous

to

personnel

and

property.

Avoid repeated and

prolonged skin contact. Do not use

near open flame or excessive heat.

Flash point of solvent is 100 F-130 F

(38 C-59 C).

STEP 2.

REMOVE

CAP

SCREWS,

LOCK

WASHERS,

AND

SPACERS

THAT

ATTACH FILTER MOUNTING BRACKET

AND INTAKE MANIFOLD TO CYLINDER

HEAD. CAREFULLY LAY FUEL AND OIL

FILTER ASSEMBLY OUT OF THE WAY OF

MANIFOLD REMOVAL.

STEP 3.

REMOVE

NUTS,

LOCK

WASHERS,

INTAKE MANIFOLD, AND GASKETS

FROM ENGINE. DISCARD GASKETS.

INSTALLATION

STEP 1.

USE NEW INTAKE MANIFOLD GASKETS;

INSTALL

GASKETS

AND

INTAKE

MANIFOLD ON ENGINE. SECURE WITH

LOCK WASHERS AND NUTS.

NOTE

WHEN

INSTALLING

MANIFOLD

MOUNTING HARDWARE, TIGHTEN

NUTS AND CAP SCREWS LIGHTLY

AT FIRST; THEN, STARTING AT

CENTER OF MANIFOLD, WORK

TS5-4310-354-14/4-30

OUTWARD

TIGHTENING

PROGRESSIVELY IN STEPS TO 30

TO 40 FOOT-POUNDS TORQUE.

REMOVAL

STEP 2.

POSITION FUEL AND OIL FILTER

STEP 1.

LOOSEN

HOSE

CLAMP

AND

ASSEMBLY AND INSTALL SPACERS,

DISCONNECT ENGINE INTAKE FLEXIBLE

FILTER MOUNTING BRACKET, LOCK

METAL HOSE. REMOVE QUICK START

WASHERS, AND CAP SCREWS.

ATOMIZER FROM INTAKE ELBOW.

STEP 3.

INSTALL QUICK START ATOMIZER IN

INTAKE ELBOW.

INSTALL ENGINE

INTAKE FLEXIBLE METAL HOSE AND

TIGHTEN HOSE CLAMP.

Figure 4-30. Intake manifold, removal and installation.

4-58