TM 5-4310-354-14

WARNING

Dry cleaning solvent, P-D-680, used

to

clean

parts

is

potentially

dangerous

to

personnel

and

property.

Avoid repeated and

prolonged skin contact. Do not use

near open flame or excessive heat.

Flash point of solvent is 100 F-130 F

(38 C-59 C).

b. Cleaning and Inspection.

(1) Wipe the instrument panel assembly clean

using a cloth dampened with solvent,

Federal Specification P-D-680, Type II.

Dry thoroughly.

(2) Inspect all instruments and gauges for

damage and loose mounting.

(3) Inspect the control cables for kinks,

TS5-4310-354-14/4-33

breaks, or any other damage.

(4) Inspect all other parts for cracks, breaks,

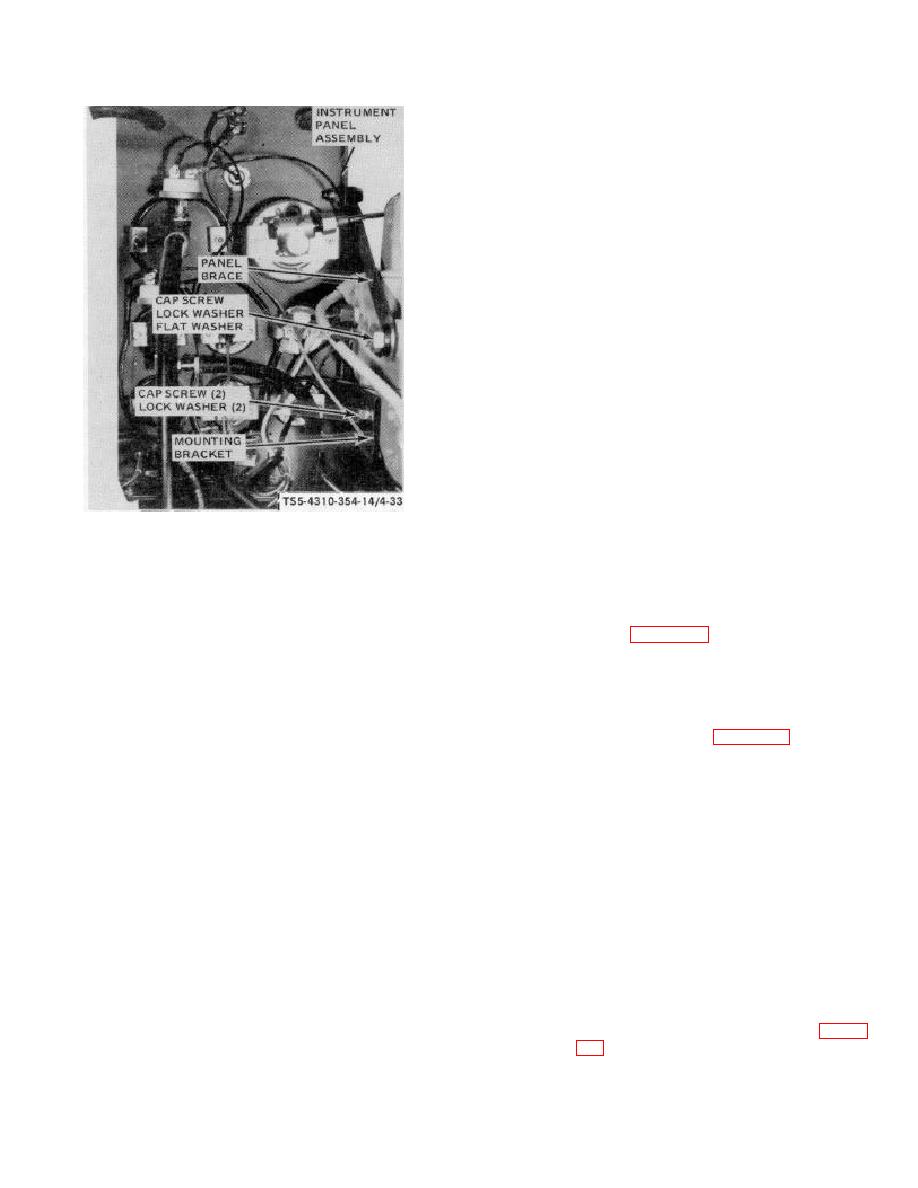

REMOVAL

distortion, deterioration, damaged threads,

or any other defect.

STEP 1.

REMOVE CAP SCREW, LOCK WASHER,

AND FLAT WASHER THAT ATTACH

c. Repair.

Repair of the instrument panel

PANEL BRACE TO ENGINE.

assembly is limited to the replacement of any damaged

component. Refer to figure 4-34 for component removal

STEP 2.

REMOVE CAP SCREWS AND LOCK

and installation.

WASHERS THAT ATTACH INSTRUMENT

PANEL

MOUNTING

BRACKET

TO

d. Installation.

ENGINE.

(1) Install the instrument panel assembly on

STEP 3.

REMOVE THE INSTRUMENT

PANEL

the unit as shown in figure 4-33.

ASSEMBLY FROM THE UNIT.

(2) Connect the idle control cable

and

INSTALLATION

compressor unloader control cable.

STEP 1.

INSTALL THE INSTRUMENT PAN EL

(3) Connect the Quick-Start control cable to

ASSEMBLY IN POSITION ON UNIT AND

the quick start assembly actuating valve

ATTACH TO ENGINE WITH LOCK

lever.

WASHERS AND CAP SCREWS.

(4) Connect the two air cleaner restriction

STEP 2.

ALIGN PANEL BRACE WITH MOUNTING

indicator hoses to the indicators.

HOLE IN ENGINE.

(5) Install the compressor oil temperature

STEP 3.

INSTALL FLAT WASHER BETWEEN

sensing bulb in the air discharge elbow.

ENGINE AND BRACE AND INSTALL LOCK

WASHER AND CAP SCREW TO SECURE

(6) Install the engine water temperature

BRACE TO ENGINE.

sensing bulb in the engine cylinder head.

Service the radiator as shown in figure

Figure 4-33. Instrument panel assembly, removal and

installation.

4-63