TM 5-4310-354-14

TS5-4310-354-14/4-37

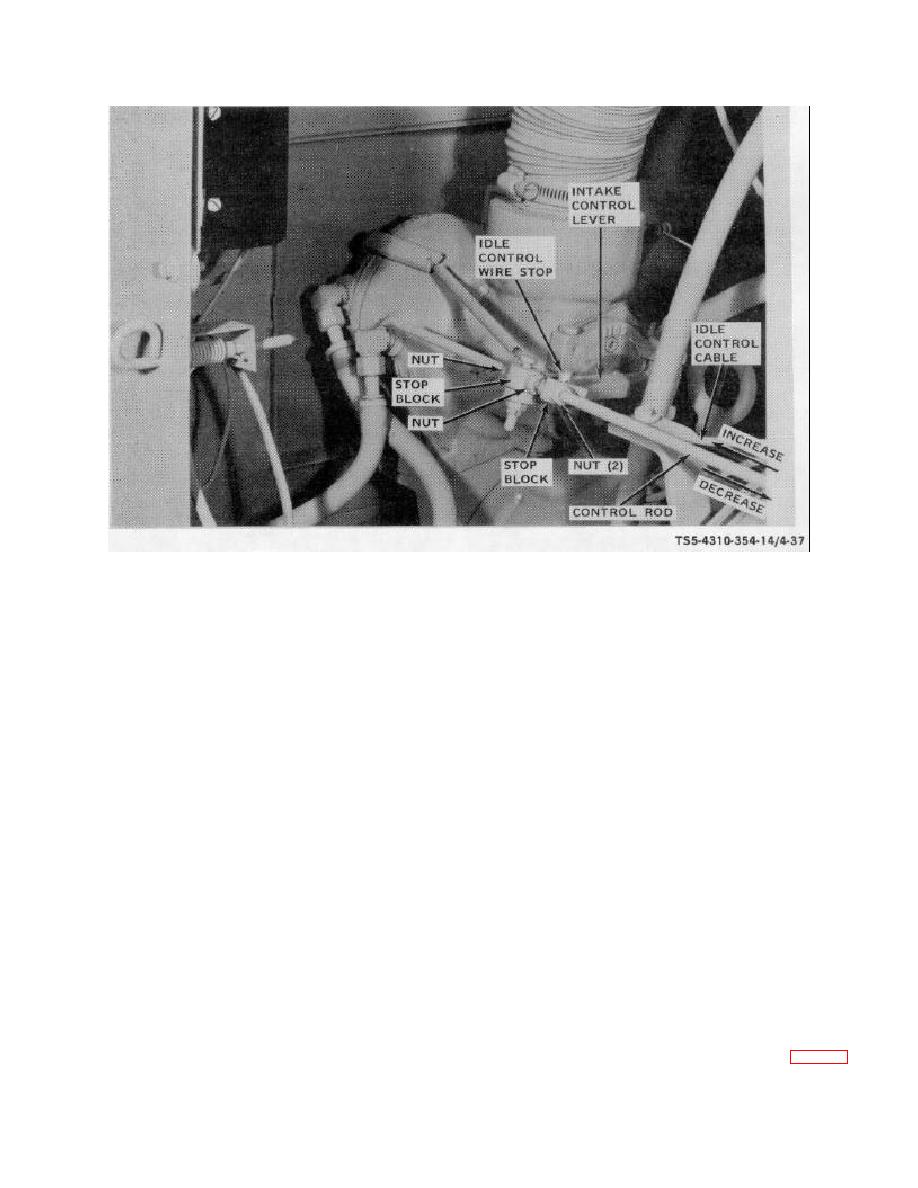

STEP 4.

UNLOCK IDLE CONTROL CABLE HANDLE ON

NOTE

INSTRUMENT PANEL AND PULL OUTWARD

THE FULL OPERATING SPEED OF 2200

TO IDLE POSITION. LOCK HANDLE. MOVE

RPM IS SET AND CONTROLLED BY THE

IDLE CONTROL CABLE ACTUATING WIRE

FUEL INJECTION PUMP GOVERNOR

STOP, AS NECESSARY, TO REST AGAINST

GROUP. REFER ANY GOVERNOR OR

ACTUATING WIRE STOP BLOCK.

(THE

FUEL INJECTION PUMP MAINTENANCE

ACTUATING WIRE STOP BLOCK MAY BE

TO DIRECT SUPPORT MAINTENANCE

MOVED ON CONTROL ROD AS NECESSARY

PERSONNEL.

TO MAKE THIS WIRE STOP SETTING.)

TIGHTEN WIRE STOP ON ACTUATING WIRE.

STEP 1.

START THE UNIT AND ALLOW TO RUN UNTIL

UNLOCK IDLE CONTROL CABLE HANDLE

COMPRESSOR

UNLOADS.

WHEN

AND PUSH IN TOWARD INSTRUMENT PANEL

COMPRESSOR UNLOADS, ENGINE SPEED

AND LOCK.

WILL REDUCE TO IDLE. CHECK THIS SPEED

ON TACHOMETER. IDLE SPEED SHOULD BE

STEP 5.

OPEN AIR SERVICE VALVE TO EXPEL AIR

1000 RPM 50 RPM.

FROM SEPARATOR ASSEMBLY CAUSING

COMPRESSOR TO LOAD. ENGINE SPEED

STEP 2.

TO ADJUST IDLE SPEED, LOOSEN NUTS ON

WILL INCREASE TO FULL SPEED. WHILE

EACH SIDE OF INTAKE CONTROL LEVER

OPERATING AT FULL SPEED, CHECK

STOP BLOCK.

TURN WHICHEVER NUT

POSITION OF IDLE CONTROL CABLE WIRE

NECESSARY TO INCREASE OR DECREASE

STOP.

THERE SHOULD BE CLEARANCE

IDLE SPEED TO 1000 RPM 50 RPM.

BETWEEN WIRE STOP AND STOP BLOCK SO

(CONTROL ROD PULLING AWAY FROM

THAT ENGINE FULL SPEED CAN BE

ENGINE

INCREASES

SPEED,

MOVING

ATTAINED.

TOWARD ENGINE DECREASES SPEED TO

POINT WHERE LOW IDLE ADJUSTING

STEP 6.

CYCLE THE COMPRESSOR SEVERAL TIMES

SCREW ON FUEL INJECTION PUMP RESTS

BY CLOSING AND OPENING AIR SERVICE

ON PUMP STOP.)

VALVE. OBSERVE TACHOMETER EACH TIME

COMPRESSOR UNLOADS TO ENSURE IDLE

STEP 3.

WHEN IDLE SPEED IS SET, TIGHTEN NUTS

SPEED REMAINS AT 1000 RPM 50 RPM.

AGAINST BOTH SIDES OF INTAKE CONTROL

LEVER STOP BLOCK TO LOCK THE STOP

STEP 7.

CLOSE AIR SERVICE VALVE AND FOLLOW

BLOCK IN POSITION ON CONTROL ROD.

NORMAL STOPPING PROCEDURE (FIG 2-7).

Figure 4-37. Speed control linkage adjustment.

4-84