TM 5-4310-354-14

valve (19). Install drain plug (18), outlet

hose adapter (17), and inlet hose adapter

(16).

(4) Install street elbow (15) in tank (27) at an

angle as close as possible to the same

angle as it was before disassembly (refer

to para 6-2.b.(3) ). Install pipe plug (14) in

street elbow (15). Install two elbows (13).

(5) Screw nipple (12) into tank cover (23).

Attach bracket (11) to separator tank with

two flat washers (10), two lock washers

(9), and two cap screws (8). Assemble

clamp (7) on nipple (12) and attach to

bracket (11) with two flat washers (6) and

two lock nuts (5).

(6) Screw minimum pressure valve assembly

(4) onto nipple (12). Install two close

nipples (3), two air service valves (2), and

two hose couplings (1).

f. Installation.

Install the oil separator assembly

6-3.

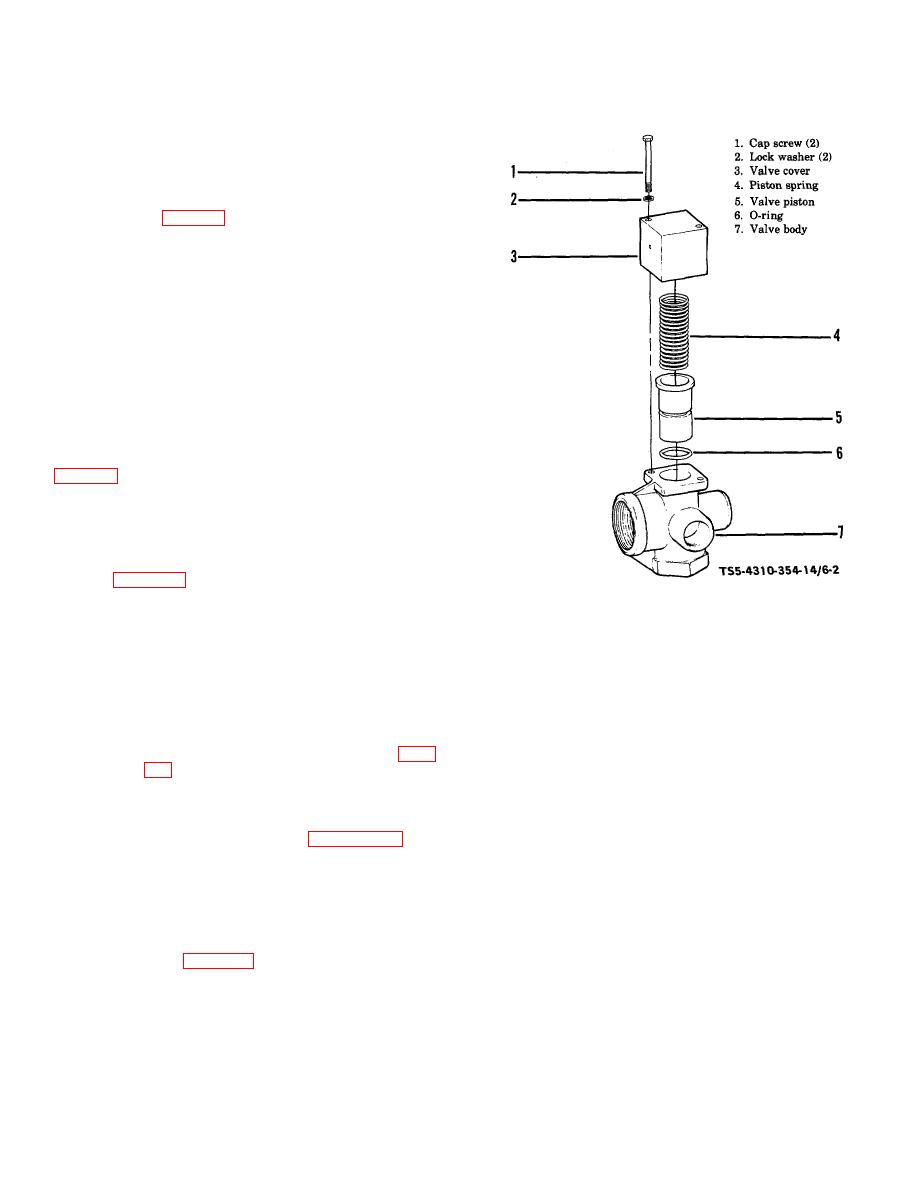

Minimum pressure valve assembly.

a. Disassembly.

Disassemble the minimum

pressure valve assembly in the numerical sequence

TS5-4310-354-14/6-2

shown in figure 6-2 as follows:

Figure 6-2. Minimum pressure valve assembly,

(1) Remove two cap screws (1) and two lock

disassembly and reassembly.

washers (2).

Carefully remove valve

cover (3) and piston spring (4).

(1) Apply a light coating of clean lubricating oil

(2) Remove the valve piston (5) and remove

or petroleum jelly on o-ring (6) to make

o-ring (6) from piston.

assembly easier.

Install o-ring (6) in

groove provided on valve piston (5).

b. Cleaning, Inspection, and Repair.

Assemble valve piston (5) in valve body

(7).

(1) Clean all parts in accordance with para

(2) Assemble piston spring (4), valve cover

5-7.f.

(3), and attach cover to valve body (7)

(2) Inspect all parts for cracks, breaks,

with two lock washers (2) and two cap

distortion, damaged threads, or any other

screws (1).

defect.

(3) Discard o-ring (6, figure 6-2) at

d. Testing.

After reassembly of the minimum

disassembly and replace.

pressure valve assembly, test as follows:

(4) Repair is limited to replacement of

defective parts.

(1) Attach the inlet of the minimum pressure

valve assembly to a controlled air source

c. Reassembly.

Reassemble the minimum

capable of producing a minimum of 100

pressure valve assembly in the reverse numerical

psi air pressure. The air source should

sequence shown in figure 6-2 as follows:

have a pressure gauge between the

control valve and the minimum pressure

valve assembly.

(2) Open the air source control valve slowly

while observing the pressure gauge. The

6-4