TM 5-4310-354-14

minimum pressure valve piston should lift

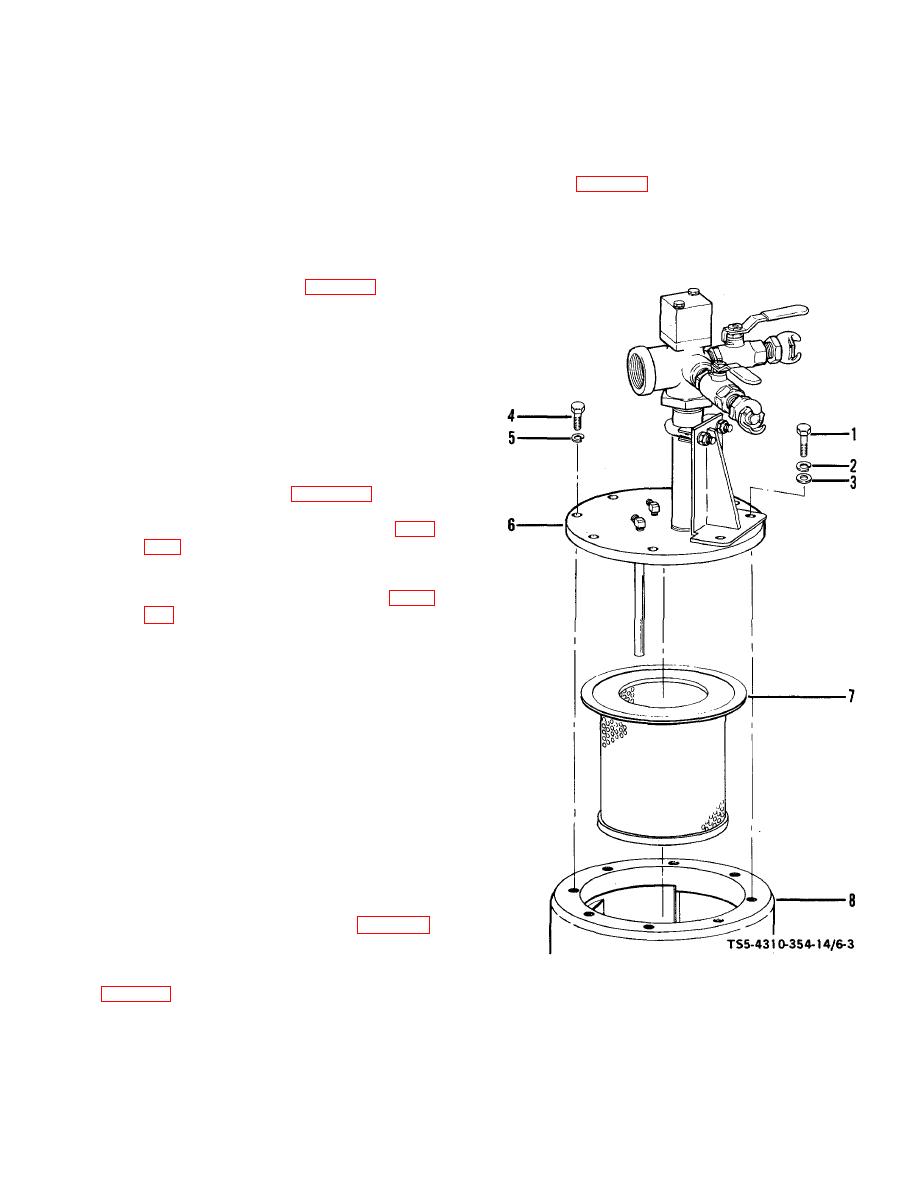

c. Installation.

off its seat at approximately 70 psi

allowing air to pass through the valve.

(1) Install the oil separator element in the

reverse numerical sequence shown in

(3) Close the control valve reducing the test

figure 6-3 as follows:

pressure to less than 70 psi.

Spring

pressure on the piston should seat the

(a) Install separator element (7) in

piston stopping flow of test air through the

separator tank (8) with flange of

minimum pressure valve assembly.

element resting on top of tank.

Should the assembly not function in this

manner, the spring (4, figure 6-2) and o-

ring (6) shall be replaced.

(4) Close the test air control valve and

remove the minimum pressure valve

assembly from the test setup.

6-4.

Oil Separator Element.

a. Removal.

(1) Disconnect air lines necessary for removal

of oil separator cover (figure 4-22).

(2) Remove the hose reel assembly (para

(3) Remove oil separator cover and element

in the numerical sequence shown in figure

6-3 as follows:

(a) Remove two cap screws (1), two

lock washers (2), and two flat

washers (3) located at support

bracket.

(b) Remove the remaining six cap

screws (4) and six lock washers (5)

attaching cover assembly (6) to

separator tank (8).

(c) Lift cover assembly (6) straight up

so that separator element (7) is not

damaged by oil pipe attached to the

underside of the cover assembly (6).

Lift out the separator element (7).

for holes, varnishing condition, distortion, or any other

TS5-4310-354-14/6-3

defect.

Figure 6-3. Oil separator element, removal and

KEY to figure 6-3:

installation.

1. Cap screw (2)

5.

Lock washer (6)

2. Lock washer (2)

6.

Cover assembly

3. Flat washer (2)

7.

Separator element

4. Cap screw (6)

8.

Separator tank

6-5