TM 5-4310-354-14

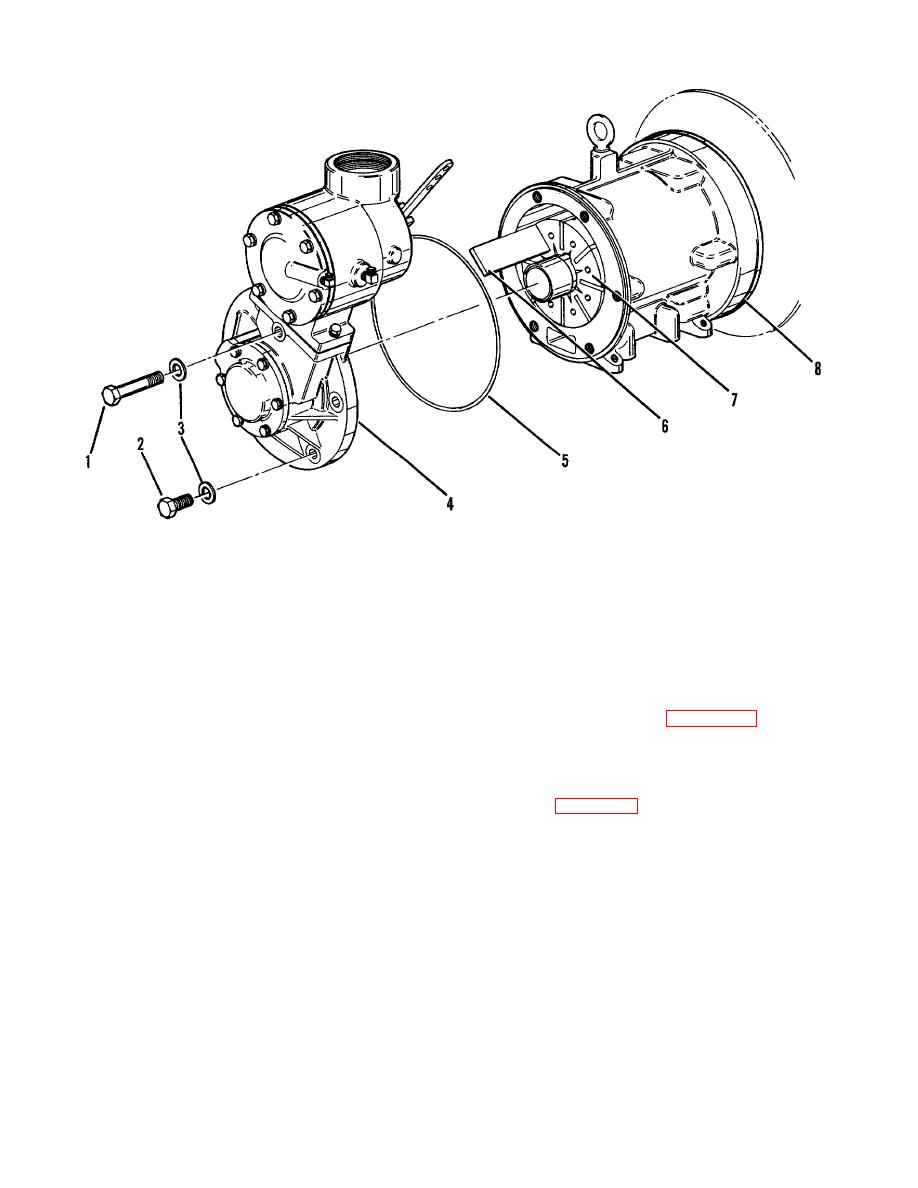

1.

Cap screw

5.

O-ring

2.

Cap screw (5)

6.

Rotor blade (8)

3.

Seal washer (6)

7.

Rotor

4.

Intake housing and

8.

Stator

end cover assembly

TS5-4310-354-14/6-10

Figure 6-10. Compressor non-drive end, disassembly, blade inspection, and reassembly

(a) Remove one cap screw (1), five cap

instrument panel momentarily to

screws (2), and six seal washers

rotate engine and compressor rotor

(3). Tap intake housing and cover

to bring blades to a position where

assembly (4) with a soft mallet while

they can be removed.

pulling away from stator (8).

Remove the housing and cover

b. Inspection.

Inspect blades for evidence of

assembly (4). Remove o-ring (5).

excessive wear.

See figure 6-11.

Blades are

excessively worn when 25 percent of covering, per side,

(b) Remove the eight rotor blades (6)

has been worn off, and shiny metal is exposed. Blades

from rotor (7) slots using a small

worn on one side only can be turned around and reused.

wire with one end bent to form a

Replace blades that have been worn /'h-inch (1.59 mm)

hook. To remove the blades which

in height (figure 6-11). Replace blades worn on both

are on the bottom of the rotor, press

sides, chipped, or damaged in any other way.

the start pushbutton on the

6-20