TM 5-4310-354-14

(11) with two lock washers (3) and screws

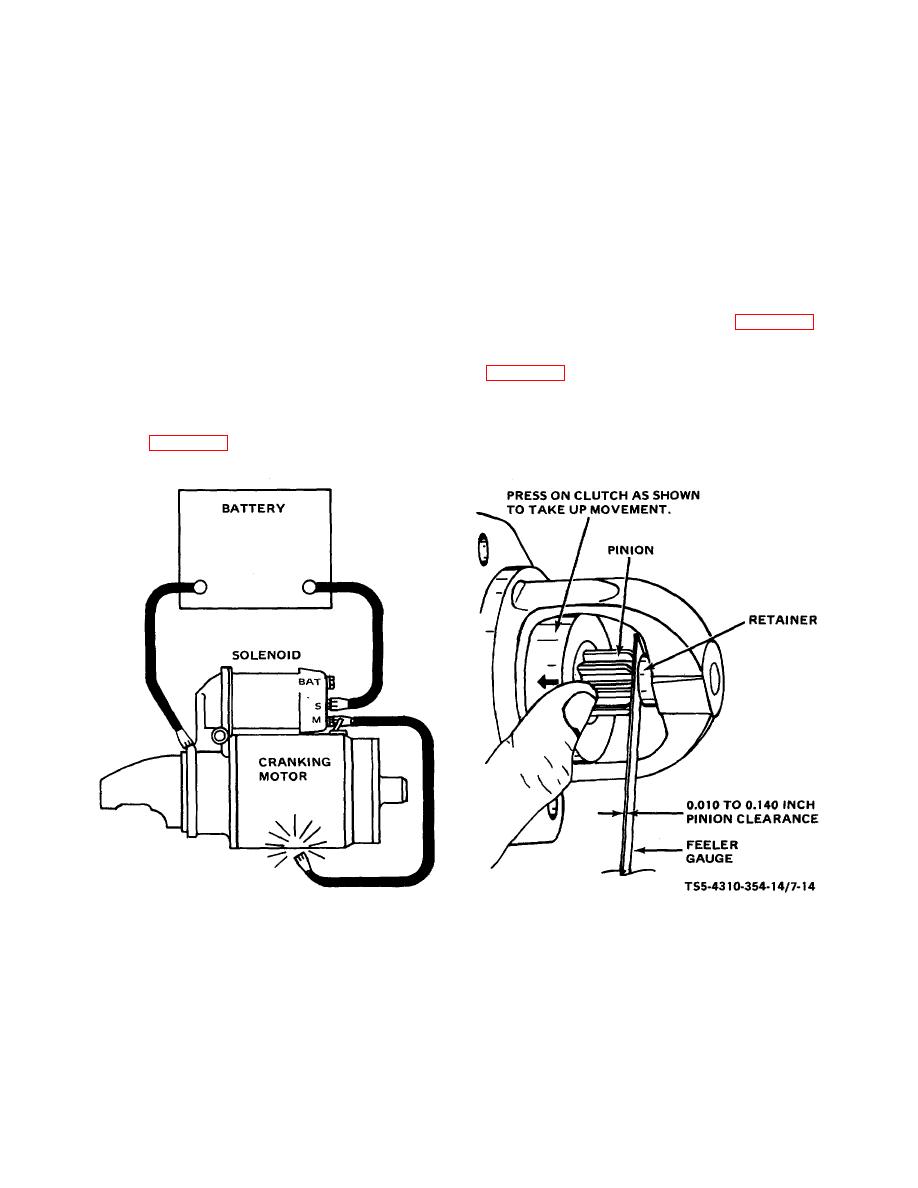

(c) MOMENTARILY flash a jumper lead from

(2). Reassemble screw and lock washer

the solenoid motor terminal to the solenoid

(1). Apply a suitable sealing compound

frame.

This will shift the pinion into

between solenoid, field frame, flange, and

cranking position and it will remain so until

junction.

the battery is disconnected.

(11) The pinion clearance cannot be adjusted but

(d) Push the pinion back towards the

should be checked after reassembly to ensure

commutator end to eliminate slack

proper clearance. Improper clearance is an

movement.

indication of worn parts. Check the clearance as

follows:

(e) Check the distance between pinion and

pinion stop as shown in figure 7-14.

(a) Disconnect the motor field coil connector

from the solenoid motor terminal and

g. Installation. Install the starting motor assembly

INSULATE IT CAREFULLY.

(b) Connect a 12-volt battery from solenoid

switch terminal to the solenoid frame

TS5-4310-354-14/7-14

A CIRUIT FOR CHECKING PINION CLEARANCE

B CHECKING PINION CLEARANCE

Figure 7-14. Checking pinion clearance.

7-14