TM 5-4310-354-14

(a) Short circuits are located by rotating the

armature in a growler with a steel strip,

such as a hacksaw blade, held on the

armature. The steel strip will vibrate on

the area of short circuit. Shorts between

bars are sometimes produced by brush

dust or copper between the bars.

Undercutting the insulation will eliminate

these shorts.

(b) Opens may be located by inspecting the

points where the conductors are joined to

the commutator for loose connections.

Poor con nections cause arcing and

burning of the commutator. If the bars are

not badly burned, leads originally soldered

to the riser bars can be resoldered.

(c) Grounds in the armature can be detected

by the use of a test lamp. If the lamp

lights when one test prod is placed on the

commutator and the other test prod on the

armature core or shaft, the armature is

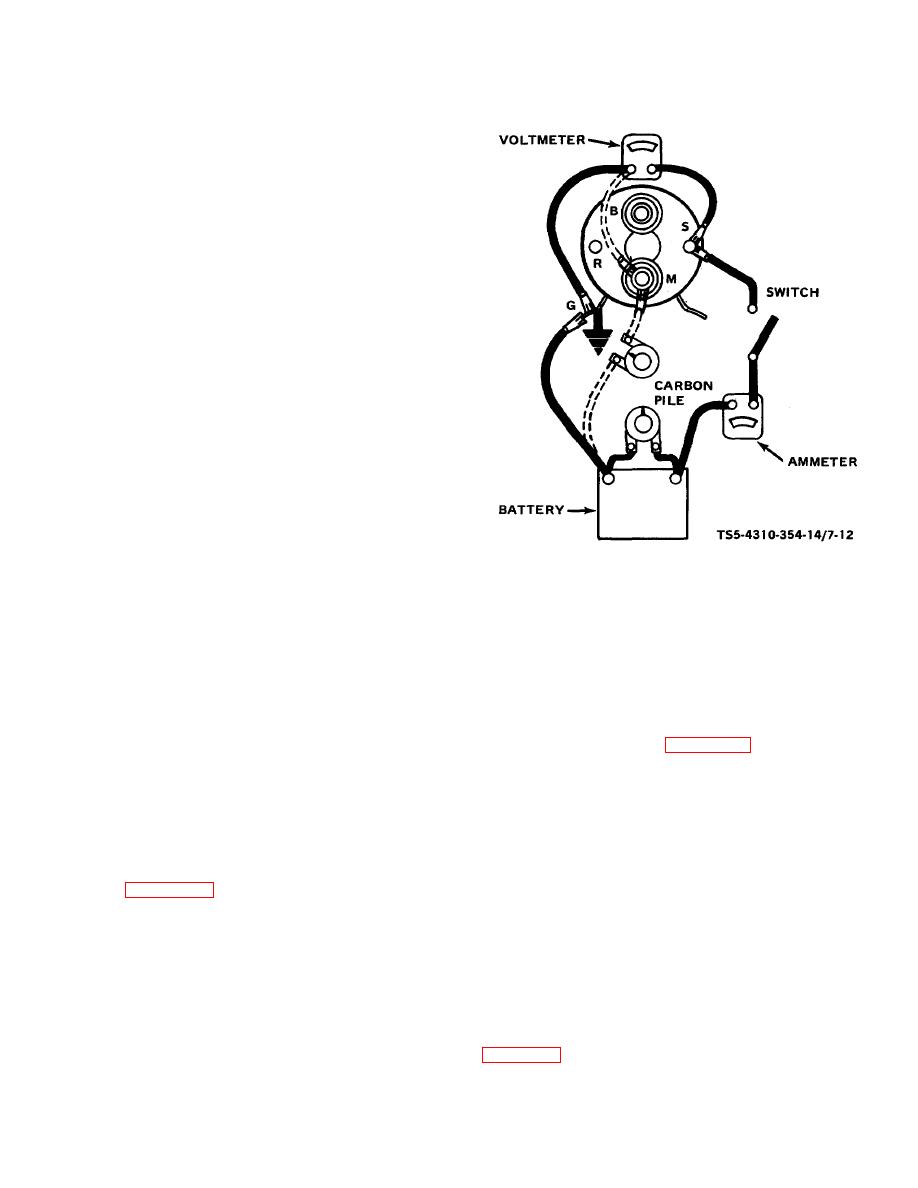

TS5-4310-354-14/7-12

grounded. If the commutator is worn,

dirty, out of round, or has high insulation,

Figure 7-12. Solenoid checking test setup.

the commutator should be turned down

and undercut.

To check the pull-in winding,

(2) Field Coils. Check the field coils for grounds

connect from the solenoid switch terminal(s),

and opens using a test lamp.

and to the solenoid motor (M) terminal.

(a) Grounds. Disconnect field coil ground

NOTE

connections. Connect one test prod to the

field frame and the other to the field

Connect the carbon pile between the

connector. If the test lamp lights, the field

battery and M terminal as shown in

coils are grounded and must be repaired

dashed lines on figure 7-12, instead

or replaced. (This check cannot be made

of across the battery, if needed, to

if the ground connection cannot be

reduce voltage to 5 volts for pull-in

disconnected.)

check.

If not needed, connect a

(b) Opens . Connect test lamp prods to ends

jumper directly from battery to the M

of field coils. If lamp does not light, the

terminal. At 5 volts, ampere reading

field coils are open.

should be 13-15.5 amps.

(3) Solenoid. Make a solenoid test setup as shown

CAUTION

in figure 7-12. Use a 12-volt battery and all

leads disconnected from solenoid. To check

To prevent overheating, do not leave

hold-in winding, make test connections to the

the pull-in winding energized more

solenoid switch (S) terminal and to ground (G).

than 15 seconds. The current draw

Use the carbon pile across the battery to

will decrease as the winding

decrease voltage to 10 volts. Observe ammeter

temperature increases.

reading. It should be 14.516.5 amperes. A high

reading indicates a shorted or grounded hold-in

f. Reassembly. Reassemble the starting motor

winding. A low reading indicates excessive

assembly in the reverse numerical sequence shown in

7-12