TM 5-4310-354-14

(1) Clean housings and end frames in

accordance with paragraph 5-7.f.

(2) Clean internal parts.

with clean, dry

compressed air.

(3) Inspect brushes for cracks, chips,

excessive wear, or any other defect.

(4) Inspect bearings for wear, scoring, pitting,

or any other defect.

(5) Inspect brush springs and arms for cracks,

breaks, distortion, or any other defect.

(6) Inspect commutator for rough spots,

discoloration, pitting, scoring, and high

mica. If commutator is rough, pitted, or

worn, turn commutator using a lathe.

Take light cuts until all pits are removed.

Remove all burrs by holding No. 00

sandpaper lightly against commutator

while armature is turning in lathe.

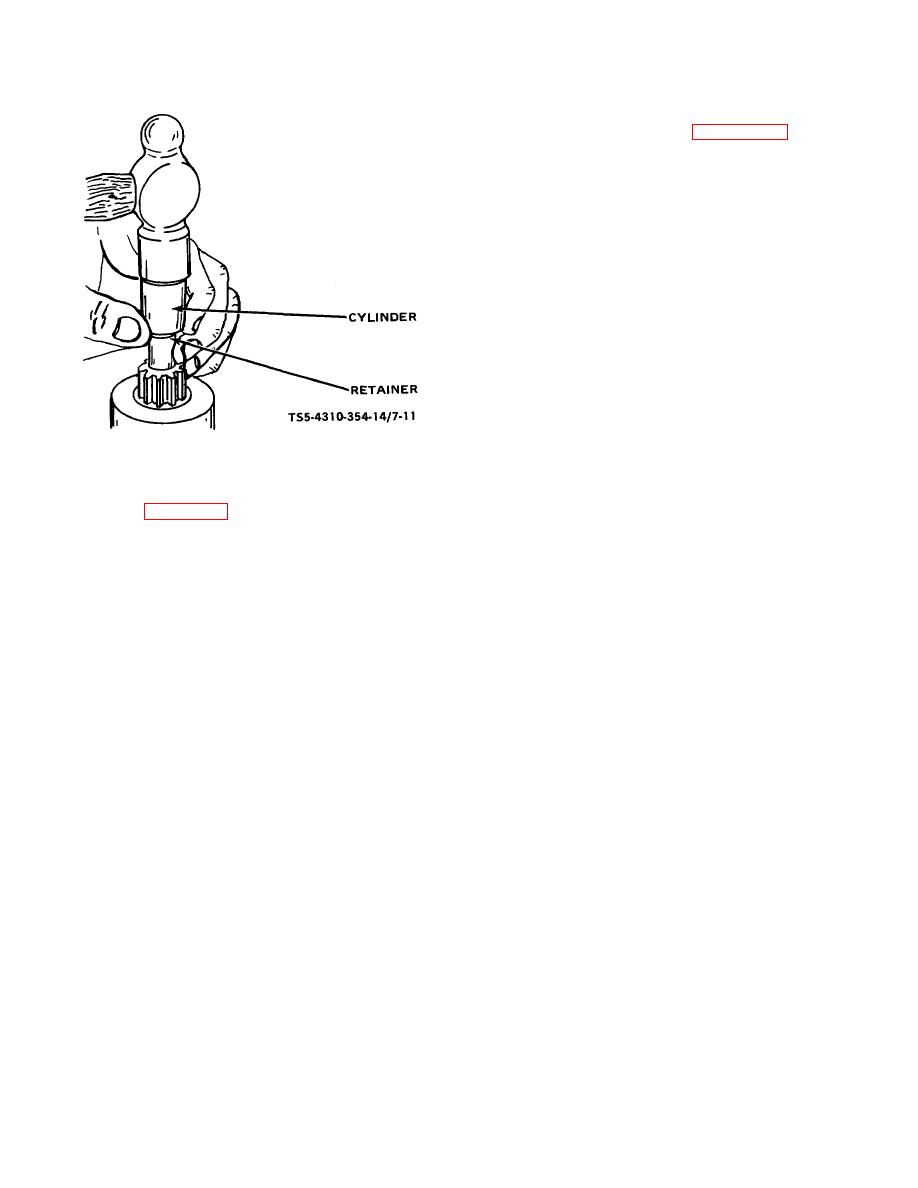

TS5-4310-354-14/7-11

Undercut mica after turning commutator.

The mica must be undercut to a depth of

Figure 7-11. Removing retainer from snap ring.

1/32-inch and width of 1/32-inch (0.79 by

0.79 mm).

(6) Remove two ground brush screws (24,

(7) Inspect commutator for out-of-round using

a dial indicator. Out-of-round shall not

exceed 0.001 inch total indicator reading.

(25), and the four brushes (26). Remove

the two brush holder pins (27), the two

(8) Inspect armature shaft for pitting, scoring,

ground brush holders (28), and two

or excessive wear.

Inspect drive

assembly for broken teeth on pinion.

insulating brush holders (29). Remove

two brush springs (30).

Check to make certain that clutch

(7) Only when necessary to disassemble

assembly moves on shaft properly. Slide

drive assembly on armature shaft to make

support packages (36), remove four nuts

(31), lock washers (32), and screws (33).

certain that splines fit properly.

Remove two brush holder supports (34)

(9) Inspect solenoid parts. Check condition of

moving core. Check contact assembly

and two ground leads (35).

(8) Remove four pole shoe screws (37) from

and terminal studs for evidence of

starter frame (41) to remove the four pole

burning, corrosion, or excessive pitting.

(10) Inspect all other parts for cracks, breaks,

shoes (38). Remove grommet (39) and,

only as needed, field coil assembly (40)

excessive wear, damaged insulation, or

from starter frame (41).

any other defect.

(11) Inspect all attaching hardware for

d. Cleaning, Inspection, and Repair.

damaged threads, cracks, or any other

defect.

CAUTION

e. Component Testing.

Do not soak or clean any insulating

(1) Armature. Check the armature for short

or electrical components such as

circuits, opens, and grounds as follows:

brushes, coils, and armature with

solvent. Do not clean overrunning

clutch and drive assembly with

solvent as this will dissolve clutch

mechanism lubricant.

7-11