TM 5-4310-354-14

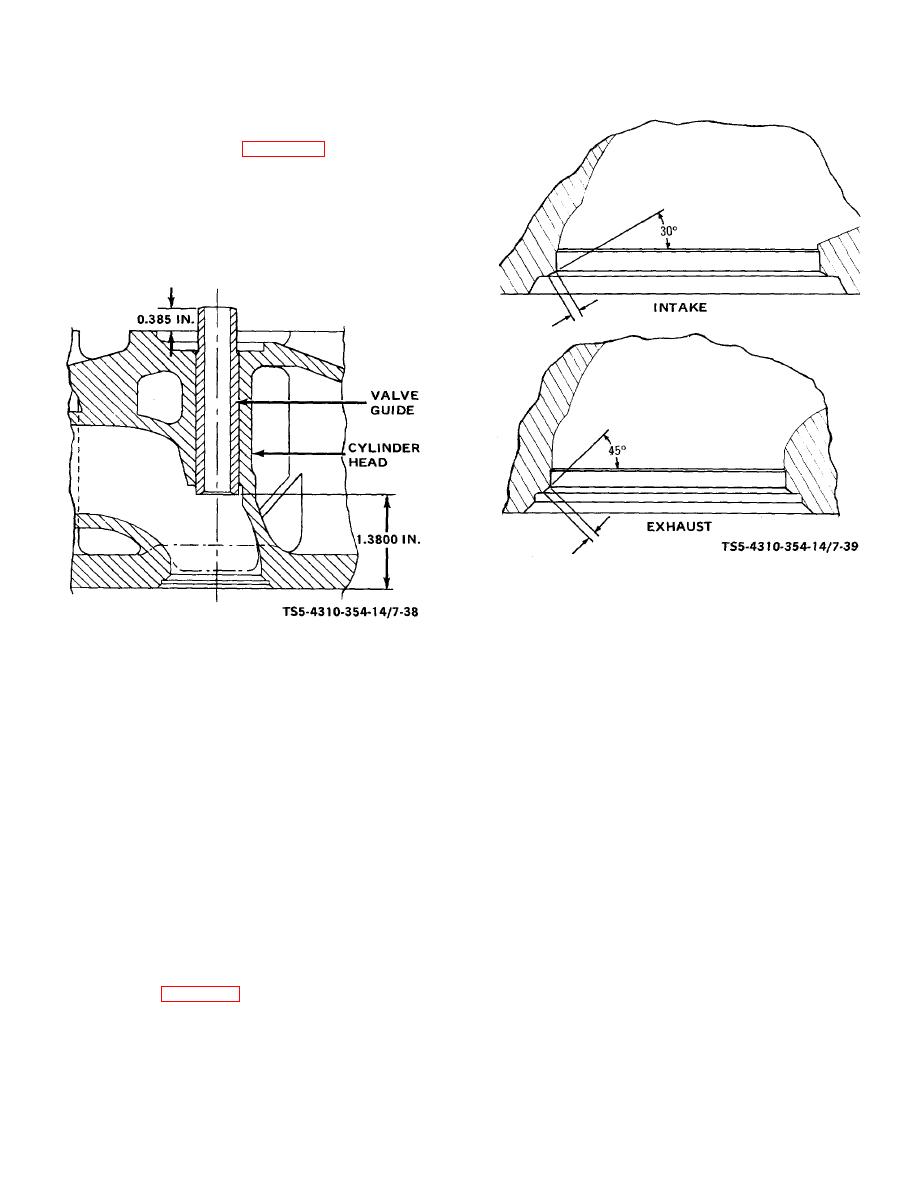

the lower edge of the valve guide to the gasket

face of the cylinder head is 1.3800 inches

(35.042 mm). See figure 7-38. After the new

guides are driven in, ream the inside diameter to

correct any squeezing in or any distortion.

Ream the exhaust valve guides to 0.3750 to

0.3760 inch (9.525 to 9.550 mm). Ream the

intake valve guide to 0.3740 to 0.3750 inch

(9.4996 to 9.5250 mm).

TS 5-4310-354-14/7-39

Figure 7-39. Valve reseating dimensions.

TS 5-4310-354-14/7-38

(15) Seating Valves . If the valves and seats are not

deeply pitted or shouldered or have been

Figure 7-38. Valve guide, installation.

refaced, grind or lap each valve to its seat as

follows:

(14) If the valve seats are pitted or if new valve

guides have been installed, the seats must be

(a) Lubricate the valve stem and apply a thin

refinished. The intake valve seats are finished

coating of good quality, medium coarse

on a 30-degree angle and the exhaust valve

grinding compound on the valve face.

seats are finished on a 45-degree angle. Use a

vibrating angle grinder-type reseating tool with a

(b) Take a light coil spring with enough

3/8-inch (9.525 mm) diameter pilot.

Lightly

tension to just hold the valve off the seat

lubricate and install the pilot into the valve guide

and insert it over the valve stem. Insert

bore. Lower the grinder head over the pilot

the valve in the valve guide.

shank until the stone just clears the valve seat.

Turn on the power and gently allow the stone to

(c) Use a reciprocating grinding tool and

contact the valve seat. Very little pressure other

rotate the valve a few times, pressing

than the weight of the stone should be used.

firmly on the grinding tool. (Avoid using a

Grind the seat sufficiently to remove shoulders

grinding tool with a continuous circular

and pits, and to provide an even, smooth

motion that will cut grooves in the valves

surface.

Do not grind any deeper than

or seat.) Release the pressure on the tool

necessary.

The finished valve seat should

and allow the spring to lift the valve from

contact the approximate center of the valve face.

its seat.

Rotate the valve 15 or 20

Refer to figure 7-39.

degrees and repeat the grinding process.

Periodically wipe off valve and seat and

inspect the seating progress. Reapply

another

7-43