TM 5-4310-354-14

plugs (49, 50, 51) are installed in head.

If

(c) Install the valve pushrods (19, figure

removed, install studs (47, 48).

(2) Cylinder head assembly. Make sure the cylinder

(d) Install the rocker arm assembly (para

block contact surface is clean of carbon

deposits. Install a new cylinder head gasket

(25) on the cylinder block. The gasket (25) must

(e) Adjust the valve clearance (para 4-50.b.

be assembled with the bead (rolled edge around

and 4-50.c.).

the combustion chamber) down. For sealing,

use any good cylinder head gasket cement.

(f) Connect instrument panel

brace

to

Proceed with installation as follows:

cylinder head (figure 4-33).

(a) Place the cylinder head assembly (24) on

(g) Install

enclosure

components

as

the block. Be careful not to damage

necessary (figure 4-17).

contact surfaces or the cylinder head

studs.

(h) Install bypass tube nipple and connect

bypass tube (figure 7-33).

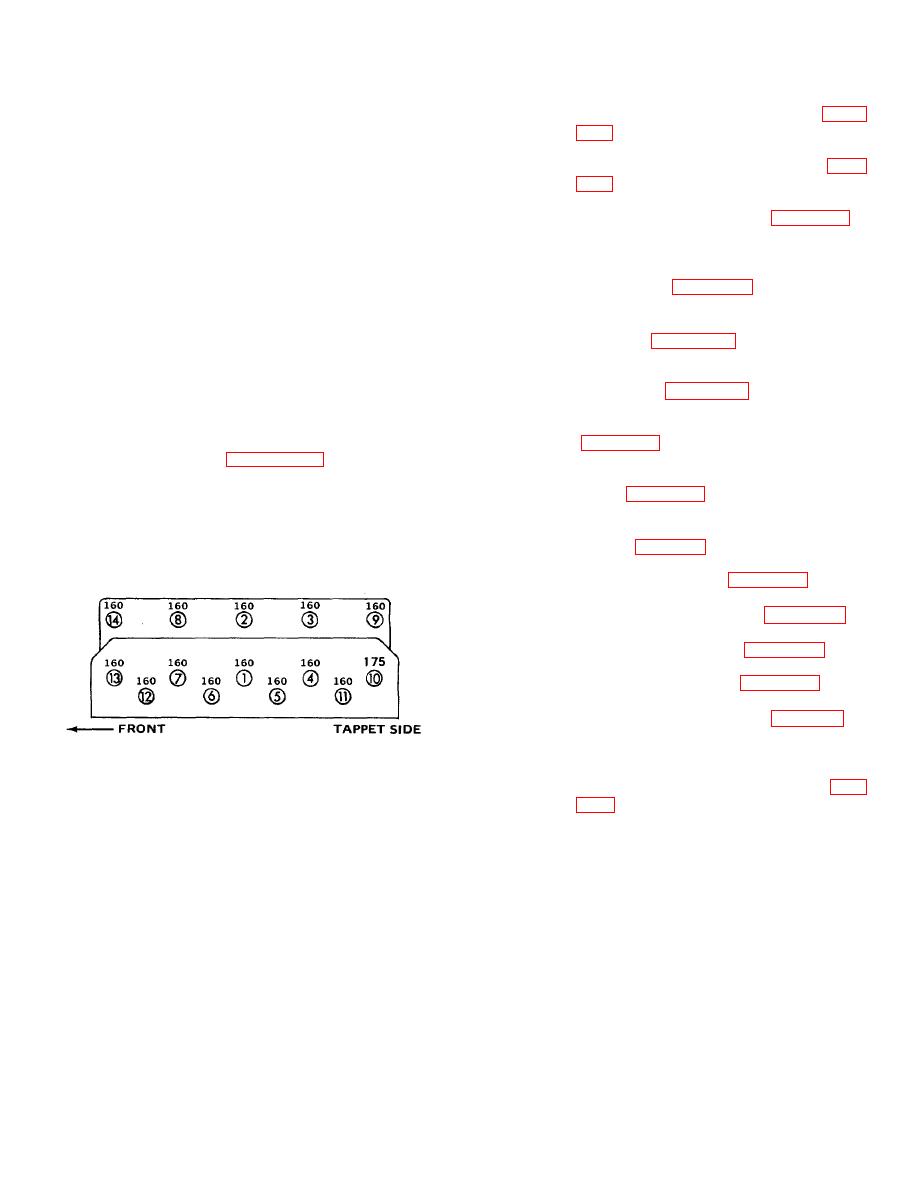

(b) Install the cylinder head nuts (20, 22) and

washers (21, 23). Tighten evenly, working

(i) Install water temperature sensing bulb

from the center of the head outward.

Refer to figure 7-40 for tightening

sequence, torque, and procedure for

(j) Install engine water temperature shutdown

tightening cylinder head to cylinder block.

switch (figure 4-35).

Tighten all nuts first to 75 foot-pounds

(10.3725 kg-m) torque in the sequence

(k) Install upper radiator hose and service the

indicated, then 125 foot-pounds (17.2875

radiator (figure 4-3).

kg-m) torque and so forth.

(l) Install intake manifold (figure 4-30).

(m) Install fuel injection nozzles (figu re 4-26).

(n) Install fuel injection lines (figure 4-28).

(o) Install exhaust manifold (figure 4-31).

(p) Install exhaust muffler group (figure 4-9).

(q) Start the engine and allow to run until

TORQUE VALUES ARE GIVEN

operating

temperature

is

reached.

DIRECTLY OVER STUD LOCATIONS.

Recheck and adjust valve clearance (para

TS 5-4310-354-14/7-40

4-50.a.).

Figure 7-40. Cylinder head nuts, tightening sequence

and torque values.

(r) Install cylinder head cover.

Install

spacers, lifting eyes, and secure lifting

CAUTION

eyes with nuts.

The cylinder head nuts must be

retightened and the valve clearance

reset after 1 hour of service.

7-45