TM 5-4310-362-14

3-4. TROUBLESHOOTING PROCEDURES (cont)

Troubleshooting

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

COMPRESSOR UNIT

Step 3. Chec k for air leaks, using soapy water if necessary. Check around all air connections.

a. Tighten loose connections.

b. Notify organizational maintenance if tightening does not eliminate leak.

3. COMPRESSOR OIL CONSUMPTION IS EXCESSIVE

Step 1. Check oil.

a. OE-30 should be used. Change oil if too light.

b. Notify organizational maintenance if oil change does not help.

Step 2. Oil rings of new or rebuilt pump may take some time to seat in cylinder walls.

a. Oil consumption should drop once rings are seated.

b. Notify organizational maintenance if oil consumption does not drop.

4. COMPRESSOR RUNS NOISY

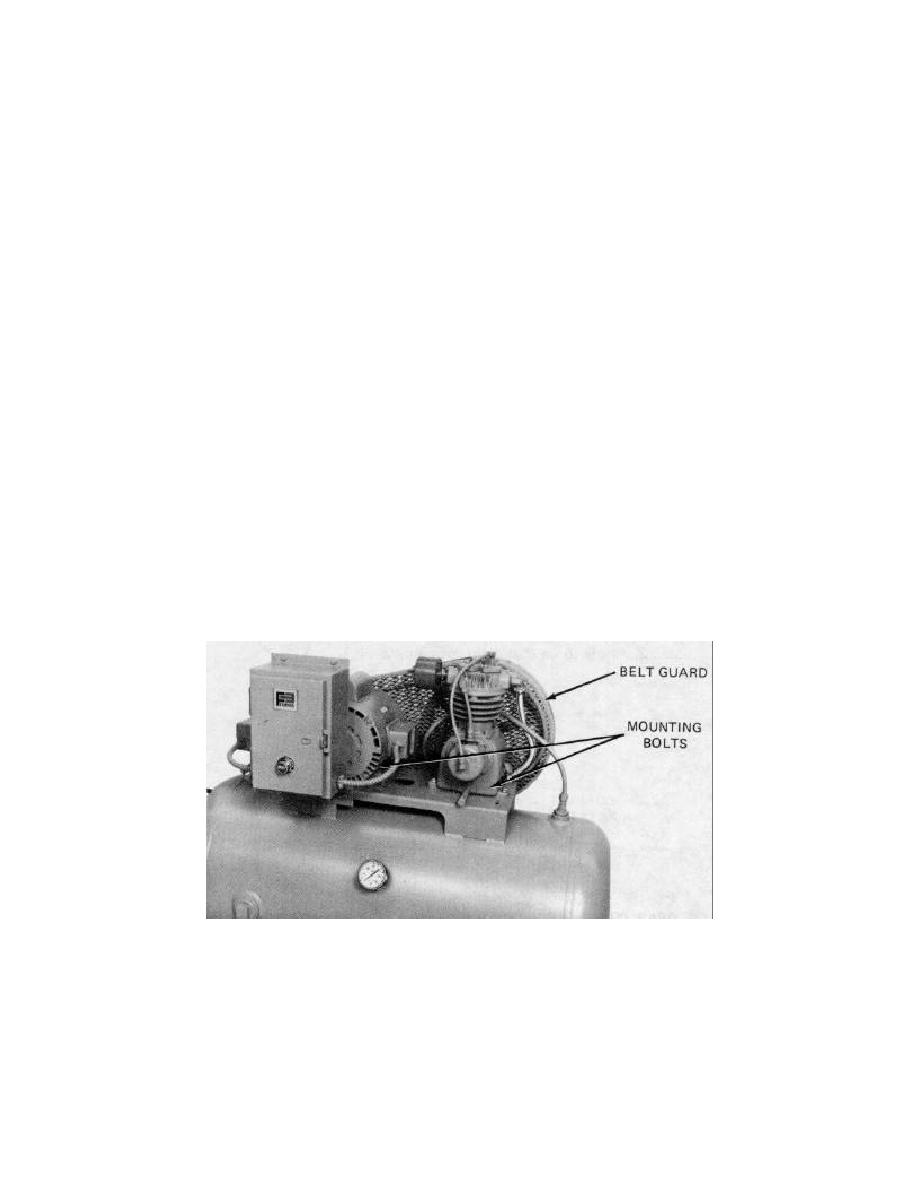

Step 1. Check for loose mounting bolts.

Tighten bolts.

Step 2. Check for loose belt guard.

Tighten mounting screws.

3-4