TM 5-4310-368-14

CHAPTER 3

OPERATOR'S MAINTENANCE INSTRUCTIONS

Section I. LUBRICATION INSTRUCTION

3-1.

TYPE OF LUBRICANT

The engine and crankcase and clutch use one grade of oil in temperatures from -10 to +130 . Another is

F

F

used in temperatures below 0 . The compressor requires one grade for temperatures ranging from -10 to

F

F

+125 . For temperatures from 0 to -65 , use the cold weather grade. Store the lubricants in clean

F

F

F

containers in a clean, dry place away from external heat. Do not allow dust, dirt or foreign material to

contaminate the oil. Keep all lubrication equipment clean and ready to use. Glycerin will be added to the

pressure gages when liquid level falls below the middle of the gage.

3-2.

CLEAN BEFORE LUBRICATION

WARNING

Dry cleaning solvent, P-D-680, used to clean parts is potentially dangerous to personnel and property.

Avoid repeated and prolonged skin contact. Do not use near open flame or excessive heat. Flash point

of solvent is 100 (38 ) - 138 (59 ).

F

C

F

C

Clean all external parts not requiring lubrication of oil using cleaning solvent and dry thoroughly. Before

lubricating the equipment, wipe all lubrication points free of dirt and grease. Clean the lubrication points after

lubrication to prevent accumulation of dirt.

3-3.

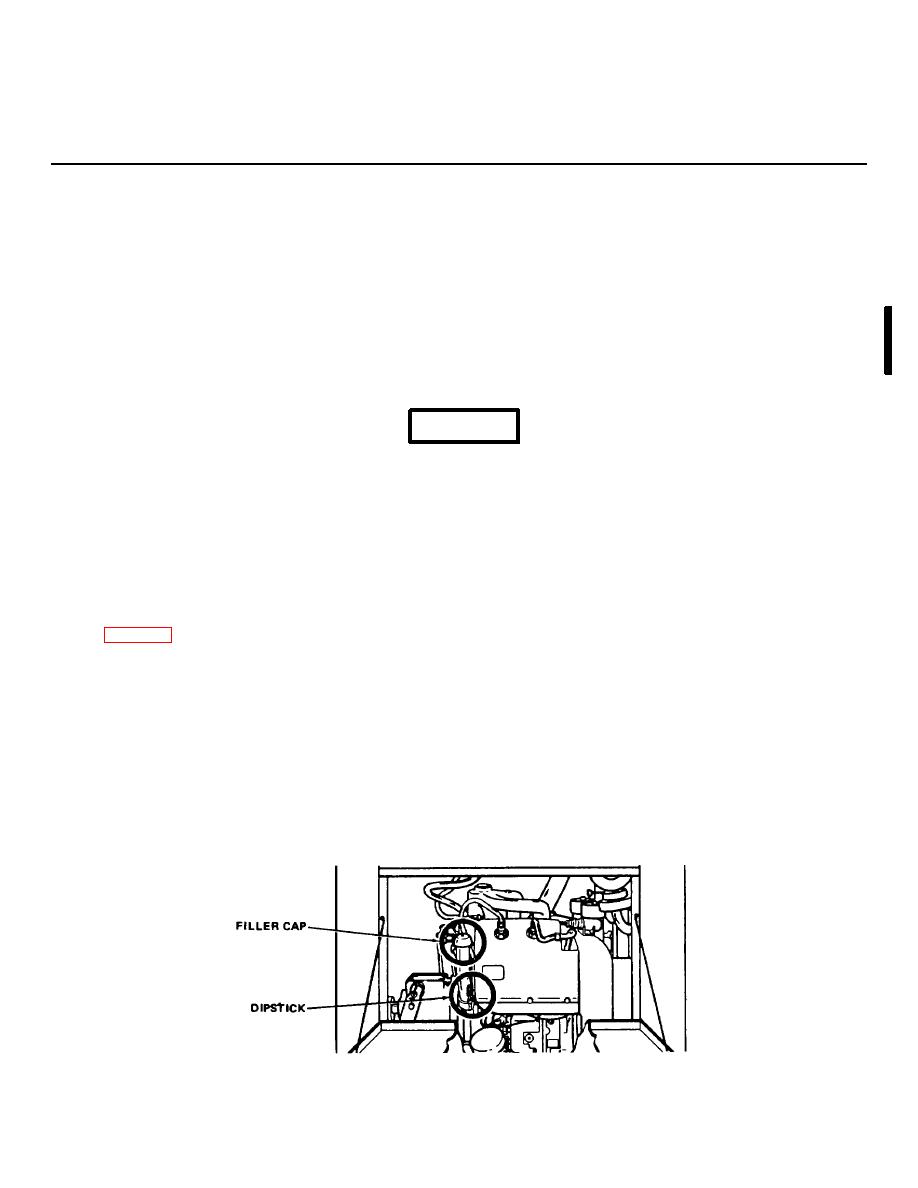

LUBRICATION POINTS

NOTE

Lubrication points (dipsticks, oil filler caps, and drain plugs) are painted red for

easy identification.

Table 3-1. Lubrication Points

1. Check level of engine crankcase with dipstick

before operation. Add oil as necessary

through oil filler.

Change 1 3-1