TM 5-4310-368-14

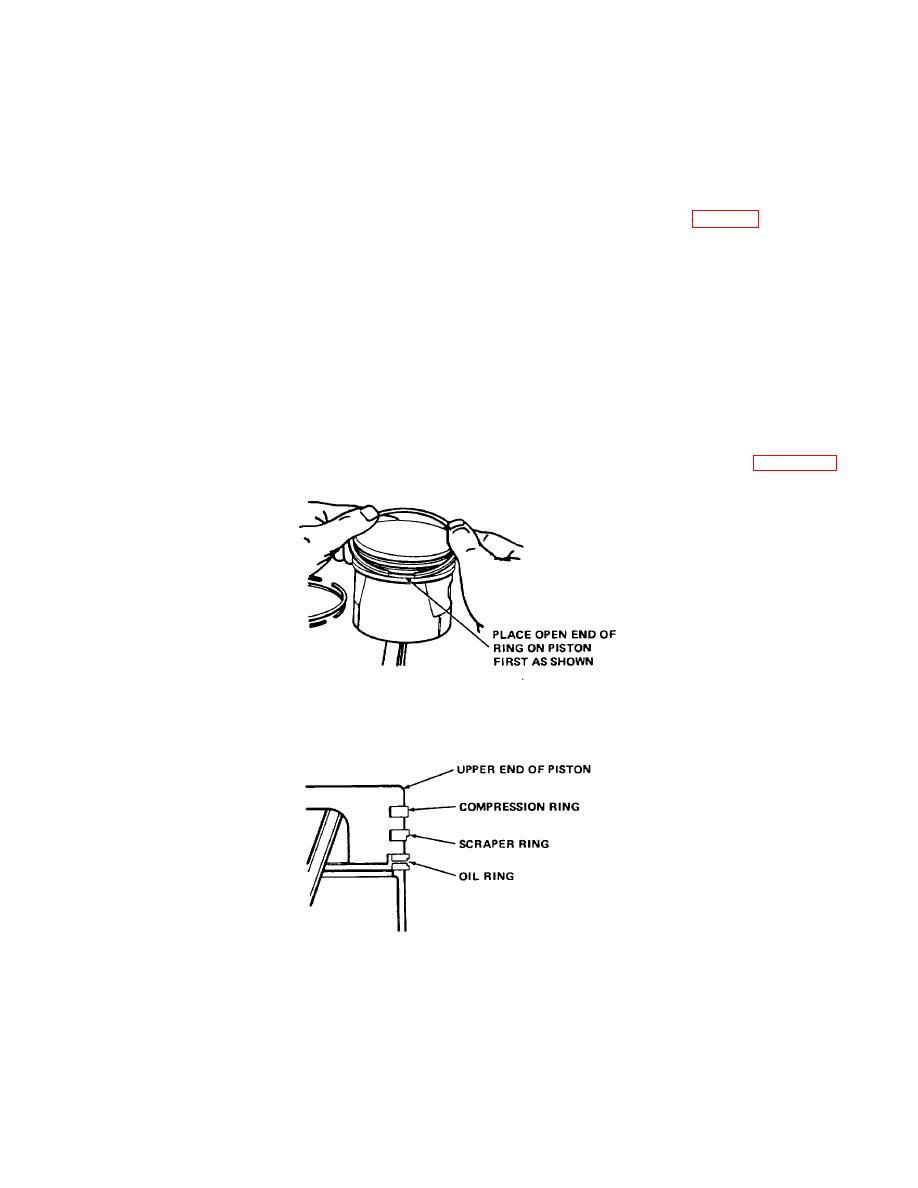

(3) Rotate the piston rings on the piston so that the end gap of the oil ring is at 12 o'clock position, the scraper

ring is at 4 o'clock position, and the compression ring is at 8 o'clock position.

(4) Apply a liberal coat of engine oil to the outside of the piston and piston rings.

(5) Install piston ring compressor to the piston and compress the piston rings.

(6) Position the piston and connecting rod assembly into the bore of the cylinder block (Fig. 6-19).

NOTE

Make sure the piston is reinstalled into the same cylinder from which it was removed.

Make sure front mark is positioned toward flywheel end of crank.

(7) Using a rubber mallet and wooden block, tap piston into cylinder.

NOTE

Take care not to damage crankshaft journals.

(8) Install connecting rod sheel bearing halves into connecting rod and connecting rod cap. See Figure 6-28.

Figure 6-26. Top of Piston

Figure 6-27. Top of Piston

6-22