TM 5-4310-368-14

6-9. INSTALLATION

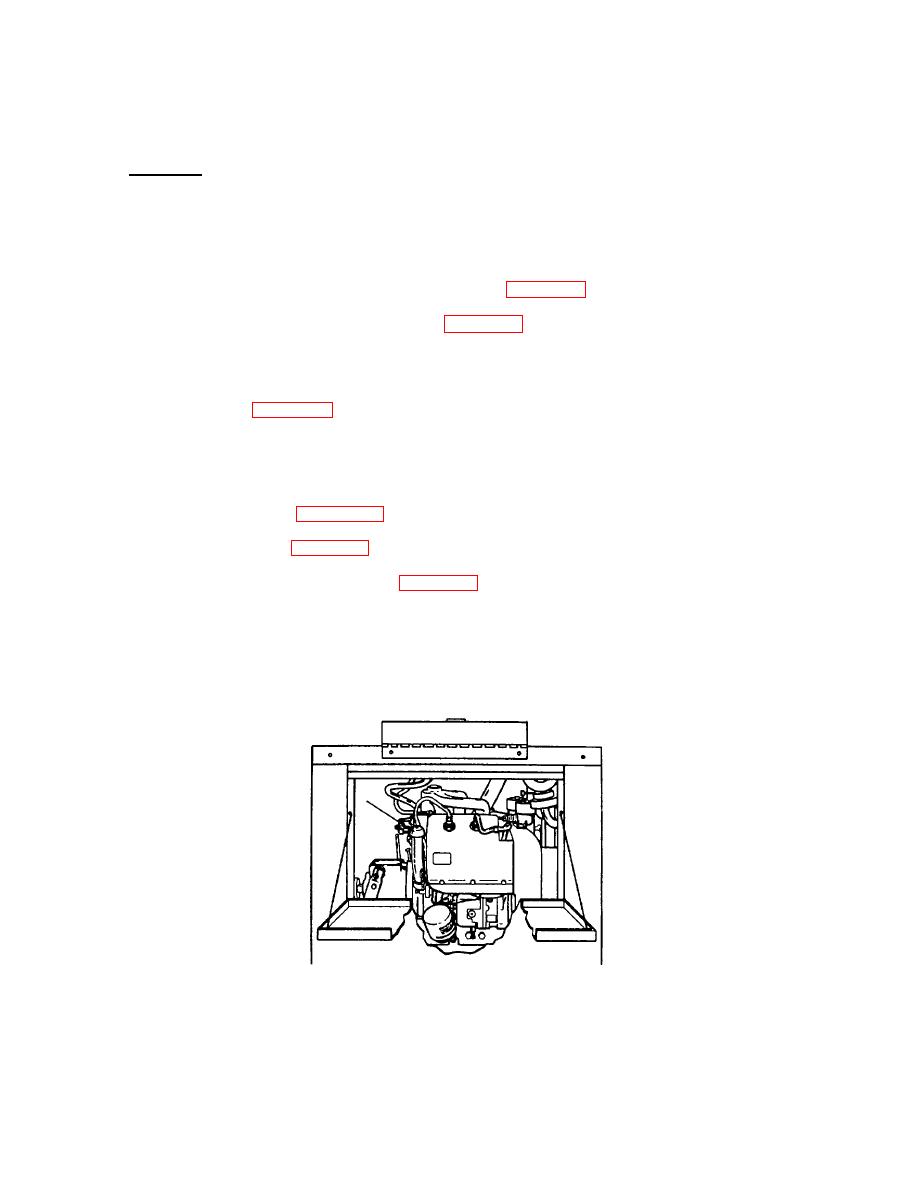

Install engine into frame.

a.

Installation

(1)

Turn belt tensioner screw counterclockwise until engine base plate is at full travel toward compressor.

(2)

Lift engine onto base plate. Align holes in engine, base plate and frame. Loose assemble four bolts

and nuts.

(3)

Attach and secure starter cable and ground cable. (Figure 6-4)

(4)

Attach and secure fuel line at fuel pump. (Figure 6-3)

(5)

Attach and secure main wire harness at throttle solenoid, magneto and oil pressure switch.

(6)

Install drive belts for compressor and alternator.

Refer to organizational maintenance for belt

adjustment. (Figure 6-5)

(7)

Attach clutch linkage at clutch. Secure with cotter pin.

(8)

Attach and secure oil drain line at engine.

(9)

Fill with proper oil. (Figure 6-37)

(10) Install roof panel. (Figure 6-1)

(11) Connect air cleaner at carburetor. (Figure 6-6)

6-10.

POST OVERHAUL RUN-IN

After a complete overhaul or rebuilding of the engine a thorough run-in period at no load is required. Start and run

the engine at no load at 1200 to 1500 RPM for about 30 minutes. The engine speed should then be increased to

2600 to 2650 RPM and run at no load for an additional 3-1/2 hours for a total of 4 hours run-in.

Figure 6-37. Engine Oil Breather

6-32