TM 5-4310-369-14

Section X. MAINTENANCE OF AIR DISCHARGE SYSTEM

not use near open flame or excessive heat. Flash

Air Discharge Assembly

point of solvent is 100F (38C).

a. Removal.

(1) Clean hose fittings with cleaning solvent, item

4-7) by depressing handle on airhose inflator assembly until

5, App. D, and dry thoroughly.

air tank gage reads 0 psi.

(2) Examine fittings for defective threads.

(2) Remove inflator gage (17), air hose (15) and

(3) Examine hose for cracks or leaks.

adapter (7).

(4) Replace defective hose assembly.

b. Cleaning and Inspection.

c. Installation.

inflator gage (17).

Drycleaning solvent, P-D-680, used to clean parts

(2) Close draincock (5).

is potentially dangerous to personnel and property.

Avoid repeated and prolonged skin contact. Do

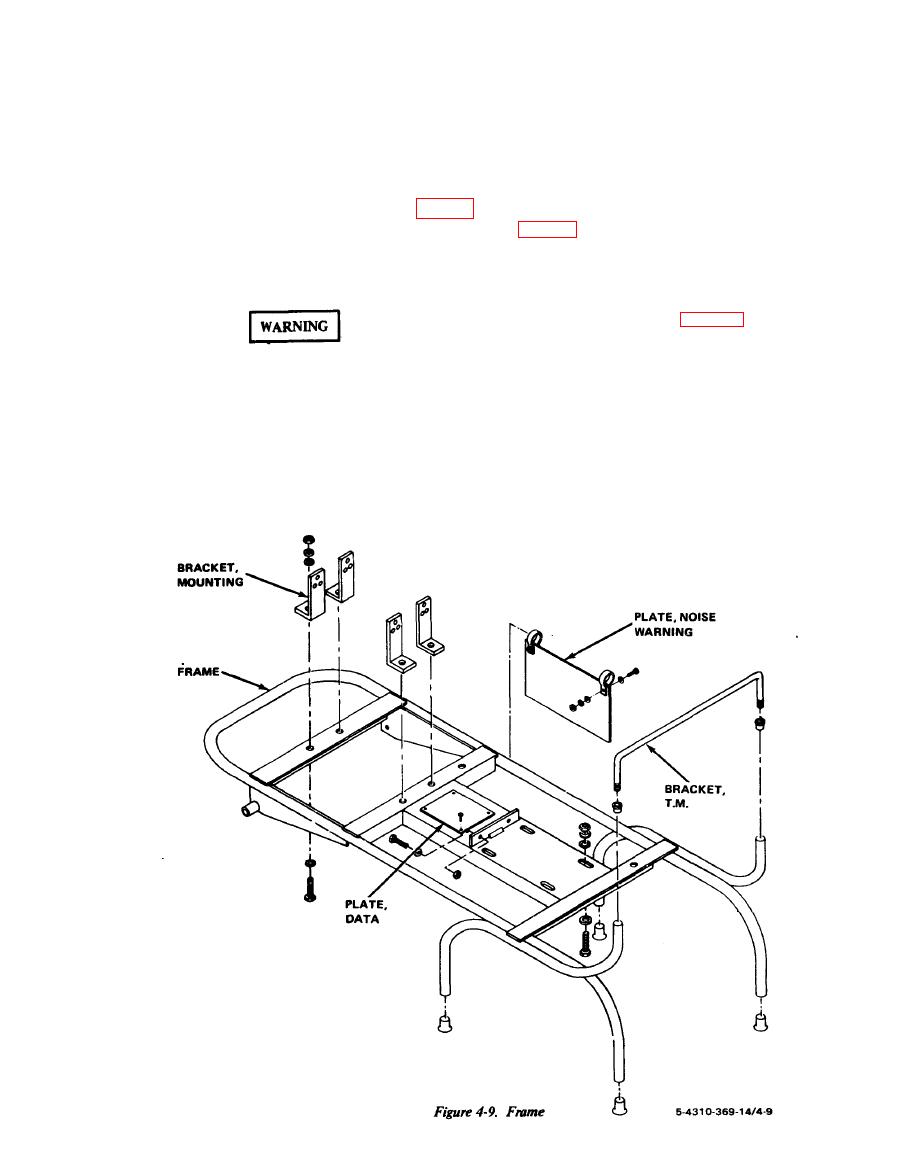

Section XI. MAINTENANCE OF HANDTRUCK ASSEMBLY

cross members. The handtruck serves as a frame for the

4-23. General

compressor and engine. The handtruck is equipped with

The compressor handtruck assembly is constructed of

wheels and inflatable tires for ease of movement.

welded aluminum tubing and structural angle aluminum