TM 5-4310-369-14

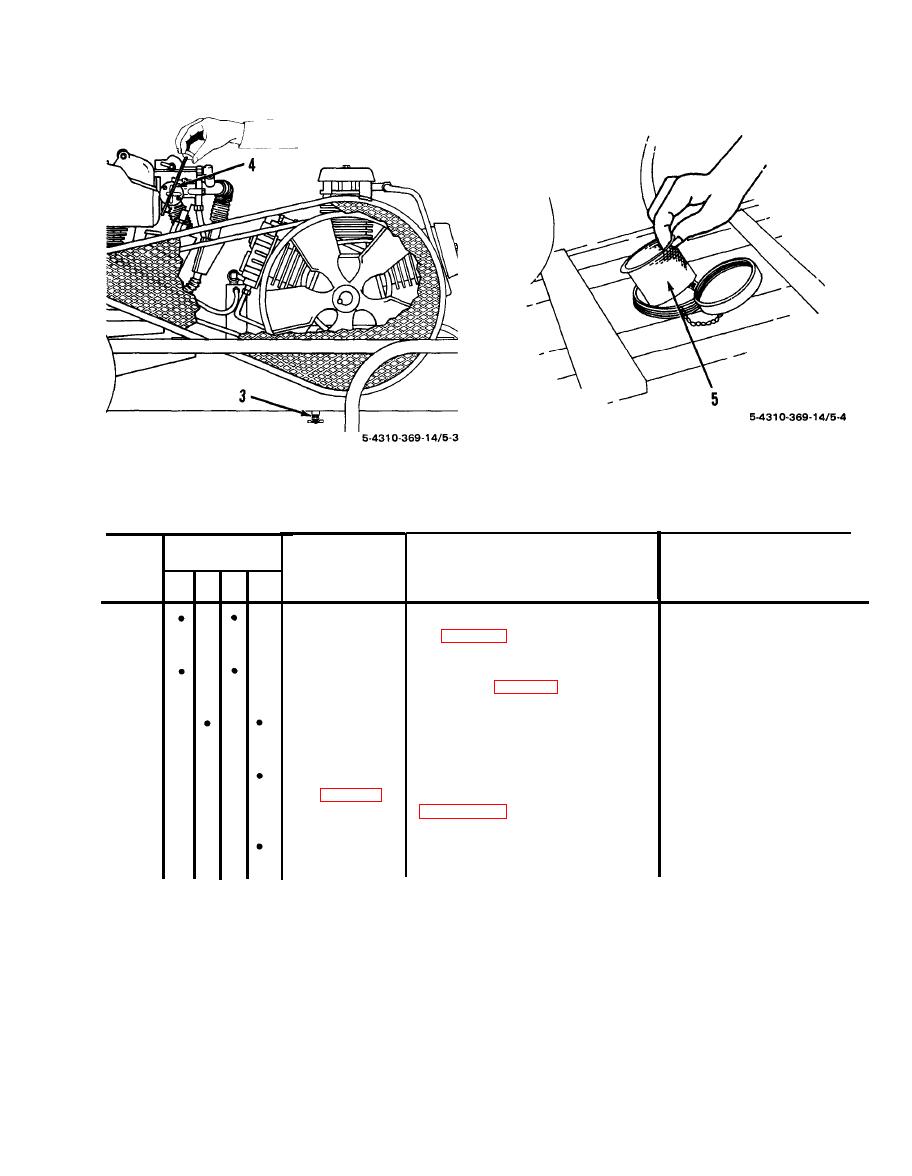

Figure 5-4. Fuel Strainer

5-3.

Engine

Service

Table 5-1. Preventive Maintenance Checks and Services - Continued

For Readiness Reporting,

Procedures

Interval

Equipment is Not

Check for and have Repaired

Item to be

Item

Ready/Available If

or Adjusted as Necessary

Inspected

No.

B

DA

W

Oil level is low.

Check oil level. Service as required.

Air Compressor

7

See figure 2-3.

Oil level is low.

Check oil level. Add oil as indicated

Engine

8

by gage. See figure 2-6.

Compressor runs noisy.

During operation, observe for any

Compressor

9

unusual noise or vibration.

10

Air filter elements are

Inspect for insecure mounting and

Air Filters (5)

clogged.

internal obstructions. Service. See

(see figure 2-8)

Tires and Tubes

Check air pressure. Proper pressure

11

is 25 psi (1.8 kg/sq cm).

Section III. TROUBLESHOOTING

b. This manual cannot list all malfunctions that may

General

occur, nor all tests or inspections and corrective actions. If a

a. This section contains troubleshooting information for

malfunction is not listed or is not corrected by listed cor-

locating and correcting most of the operating troubles which

rective actions, notify your supervisor.

may develop in the compressor. Each malfunction for an

individual component, unit, or system is followed by a list

NOTE

of tests or inspections which will help you to determine

Before you use this table, be sure you have

corrective actions to take. You should perform the tests/

performed all applicable operating checks.

inspections and corrective actions in the order listed.