TM 5-4310-369-14

NOTE: Within designated interval, these checks are to be performed in the order listed.

WWeekly

AAfter

BBefore

DDuring

Procedures

For Readiness Reporting,

Interval

Item to be

Equipment is Not

Check for and have Repaired

Item

Inspected

Ready/Available If

No.

or Adjusted as Necessary

AW

B

D

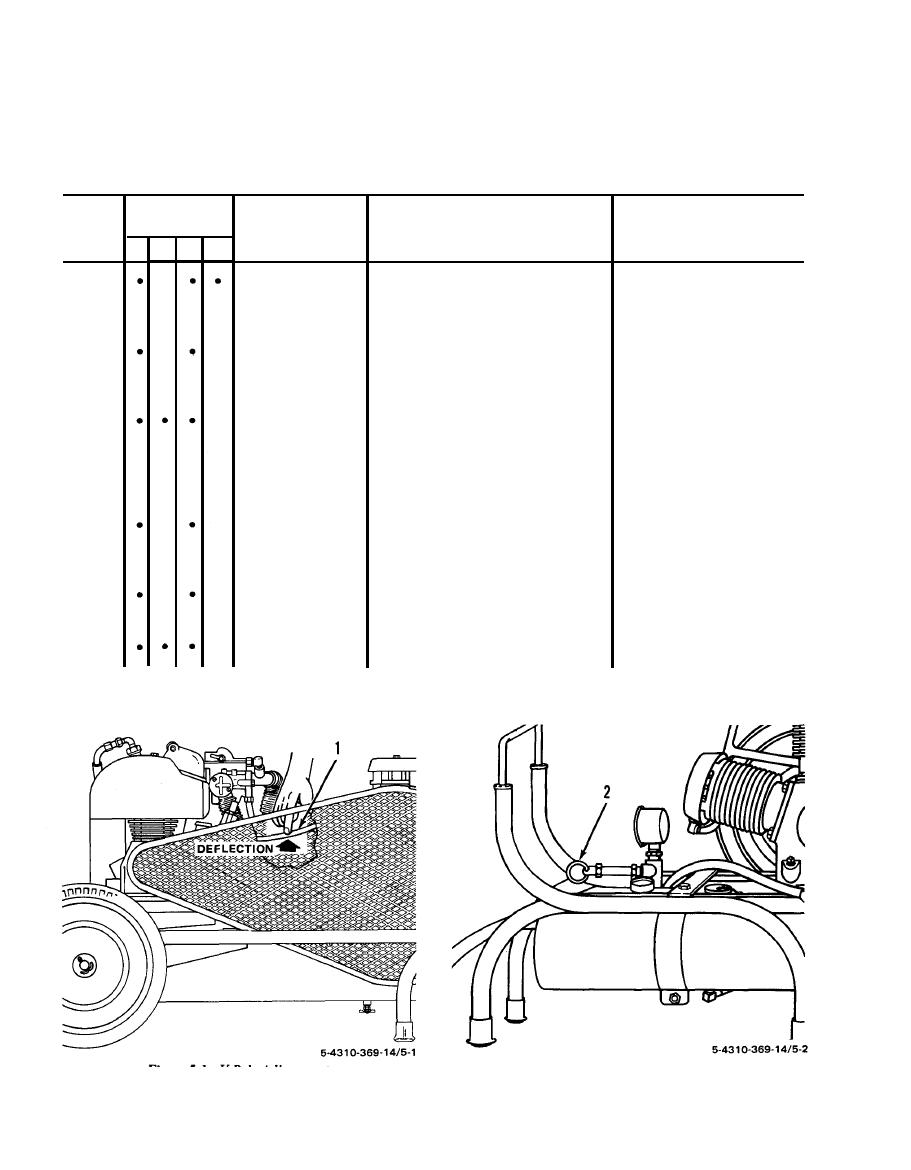

Inspect for proper tension. Deflec-

Drive Belts (1)

Belts are cracked or cut.

1

tion is 3/4 to 1 inch midway between

pulleys. Inspect for cracks or cuts.

Inspect for proper operation. Pull

2

Safety Release

Release valve leaks air.

ring to check for freedom of move-

Valve (2)

ment.

Inspect for damage and insecure

3

Controls are damaged or

Controls and

mounting. With the unit operating,

loose.

Instruments

inspect for proper operation. Normal

operating pressure is 140-175 psi

(9.8-12.3 kg/sq cm).

4

Air Receiver

Open draincock to drain water from

the tank. After water is drained,

Draincock (3)

close draincock.

5

Check oil level in engine crankcase

Engine Oil (4)

with dipstick.

6

Check fuel level and fuel strainer (5).

Fuel Tank

Figure 5-1. V-Belt Adjustment