TM-5-4310-389-14

e.

Pull in the new piston pin bushing flush; ensure the oil bores in the bushing and connecting rod coincide.

NOTE

The connecting rod bearings (6) are of the finished type. They are made of two ha]f-shells

and correspond to the possible repair sizes of the crank pins and are available in six sizes.

The bearings cannot be reconditioned.

f.

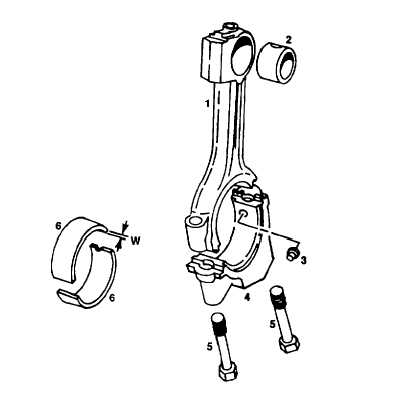

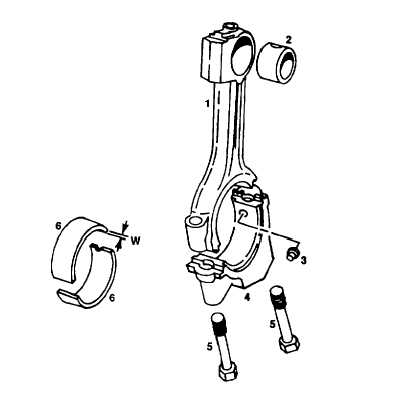

Assemble the connecting rod bearing cap (4) to connecting rod (1); ensure that they bear the same identification

number (figure 4-19)

Figure 4-19. Connecting Rod Assembly

9.

Mount bearing caps and tighten bolts (5) according to torque specifications listed in Appendix F.

h.

Set the precision gauge to the basic inner diameter size by means of a micrometer frame. See specifications in

table 4-5.

i.

Measure connecting rod bearing bore at points 1 and 2 in planes a and b (figure 4-20). Note any contraction,

out-of-roundness, or conicity.

4-50