TM-5-4310-389-14

j.

If the readings keep within the limits of the specifications in table 4-5, the respective bearing bores are in

acceptable condition and the necessary preload will be obtained after installation of new bearing shells.

k.

If the recordings at the bearing bore deviate only slightly from the specified values, the measurements must be

repeated when the new shells are installed.

1.

Remove bearing cap and insert new bearing shells.

m.

Refit bearing cap, then preload and tighten down according to torque specifications listed in Appendix F. Repeat

measurement.

n.

If the recordings show that the bearing tolerances remain up to a maximum of 0.020 mm above the values

indicated in the specifications in table 4-5, the connecting rod is still fit for use.

Otherwise it must be replaced. It is not permissible to restore the preload by reworking the parting faces on the

connecting rod bearing bore or shimming the shells.

o.

Mark matching bearing shells and connecting rod.

p.

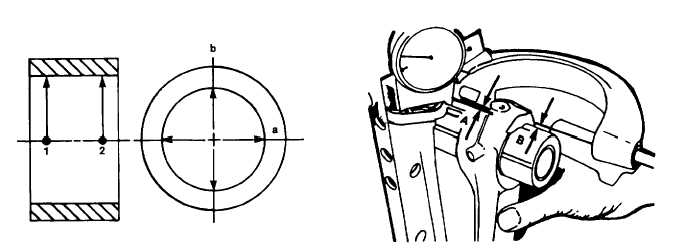

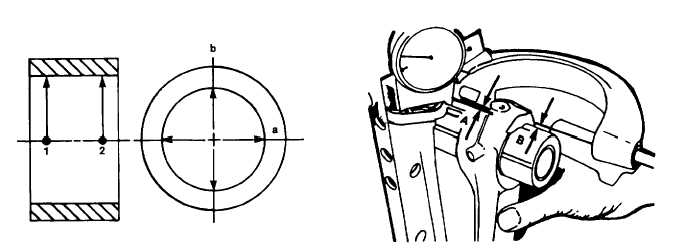

Check connecting rod with mounted small end bushing (2, figure 4-19), but without connecting rod shells (6,

figure 4-19), for parallelism (figure 4-21). Use a connecting rod tester.

NOTE

When measuring the parallelism with the plug gauge, the deviation should not exceed a=O.08 mm over a

distance of a=100 mm.

q. Check connecting rod for squareness; A and B should be equal (figure 4-22).

Figure 4-20. Measuring Piston Pin Bushing

Figure 4-21. Checking Connecting Rod

Connecting Rod Bearing Bore

for Parallelism

4-51