TM 5-4310-393-14

e.

Torque cap screws (Figure 5-1, Items 5 and 9) to 51 6 lb -ft (70 Nm) and cap screws (13) to 22.13 Ib.-ft (30

Nm).

5-6 2. FUEL INJECTION PUMP.

This task covers: A. Test B. Remove C. Install D. Adjust

Tools:

Materials/Parts:

Tool Kit, General Mechanic's Set

Diesel Fuel NSN 9140-00-268-5294

Shop Equipment, Automotive

Lubricating Oil

Maintenance and Repair

Shim Set

Testing Device for Injection

Equipment Conditions:

Equipment 60462800

Fuel Lines and Check Valve Removed

Dial Gauge, 61208700

Spill Device, 66503001

Socket Wrench, 30 mm, 66833500

Special Wrench, 60600000

A.

Test.

1.

Testing the Fuel Injection Pump.

NOTE

Perform this test both before removal

of the injection pump from the engine

and after re-installation.

WARNING

DEATH OR SERIOUS INJURY COULD

OCCUR IF FUEL IS NOT HANDLED

CAREFULLY. USE IN A WELL

VENTILATED AREA AWAY FROM

OPEN FLAME, ARCING EQUIPMENT,

IGNITION SOURCES, HEATERS, OR

EXCESSIVE HEAT. ENGINE MUST

BE

TURNED

OFF

AND

COOL

BEFORE

REFUELING.

ALWAYS

STORE FUEL IN PROPER, MARKED

CONTAINERS. DO NOT SMOKE.

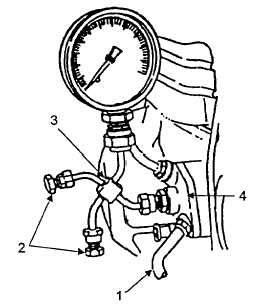

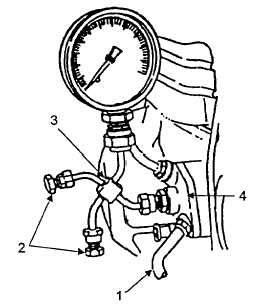

FIGURE 5-2. INJECTION PUMP TEST

a.

Connect fuel hose (Figure 5-2, Item 1) from fuel tank to injection pump (4).

b.

Ensure the extra fuel device button is not pulled out If the button is extended, push it back in.

c.

Connect testing device 60462800 (3) to injection pump (4). Ensure side connections (2) are tightly

capped.

d.

Loosen the pressure gauge connection and crank the engine until trapped air is removed from the

system.

e. Tighten pressure gauge connection.

CAUTION

Do not scratch or mar mating surfaces of pump body or cover. The fuel injection

pump may leak or otherwise malfunction after reassembly.

5-8