TM 5-4310-393-14

f. Slowly crank the engine by hand. As the engine is cranked, read fuel injection pressure on the gauge

Injection pressure should be 4350 to 5075 psi (300 to 350 bar) Stop cranking engine and observe If pressure Is

maintained If pressure drops below 3625 psi (250 bar) within 10 to 15 seconds, then injection pump is not in working

order.

g.

Depressurize fuel injector by loosening side nuts (2).

h. Remove testing device 60462800 (3).

B.

Remove.

1.

Removing the Fuel Injection Pump

a. Move throttle control lever to the STOP position and pull out the extra fuel button

CAUTION

Do

not

scratch

or

mar

mating

surfaces of pump body or cover. The

fuel injection pump may leak or

otherwise

malfunction

after

reassembly.

b.

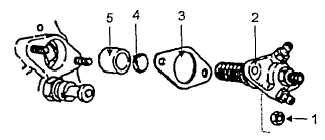

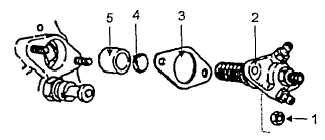

Remove two hex nuts (Figure 5-3,

Item 1) and remove injection pump (2).

c.

Remove shim(s) (3), plate (4), and

tappet (5)

FIGURE 5-3. FUEL INJECTION PUMP - REMOVAL

WARNING

DEATH OR SERIOUS INJURY COULD OCCUR IF FUEL IS NOT HANDLED

CAREFULLY. USE IN A WELL VENTILATED AREA AWAY FROM OPEN FLAME,

ARCING EQUIPMENT, IGNITION SOURCES, HEATERS, OR EXCESSIVE HEAT.

ENGINE MUST BE SHUT DOWN AND COOL BEFORE REFUELING. ALWAYS

STORE FUEL IN PROPER, MARKED CONTAINERS. DO NOT SMOKE.

WARNING

DEATH OR SERIOUS INJURY COULD OCCUR IF COMPRESSED AIR IS DIRECTED

AGAINST THE SKIN. DO NOT USE COMPRESSED AIR FOR CLEANING OR

DRYING UNLESS THE PRESSURE HAS BEEN REDUCED TO 30 PSI (2.06 BAR) OR

LESS. WHEN WORKING WITH COMPRESSED AIR ALWAYS USE CHIP GUARDS,

EYE PROTECTION, AND OTHER PERSONAL EQUIPMENT.

5-9