TM 5-4310-451-14

5-36. PISTON REPAIR (Con’t).

WARNING

Compressed air used for cleaning or drying purposes, or for clearing restrictions, should never

exceed 30 psi (207 kPa). Wear protective clothing (goggles/shield, gloves, etc.) and use caution to

avoid Injury to personnel.

4.

Dry parts with compressed air.

5.

Inspect all parts for damage. Replace damaged parts.

NOTE

Piston, sleeve bearing, and piston pin are a matched set and must be replaced as an assembly.

6.

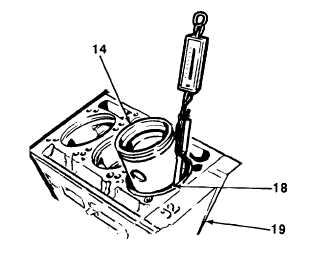

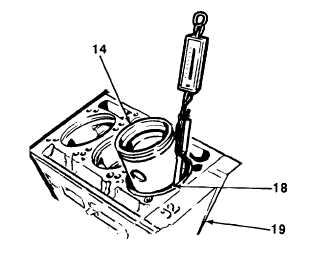

Measure diameter of piston skirt (14) and check

for out-of-round. Diameter must be at least

4.2428 in. (10.7767 mm) at any point.

7.

Check piston skirt-to-cylinder sleeve clearance

as follows:

(a)

With cylinder sleeve (18) installed In

engine crankcase (19), install piston skirt

(14) up- side down into cylinder sleeve.

(b)

Using feeler gage and spring scale, deter-

mine feeler gage thickness required to

withdraw feeler gage from between piston

skirt (14) and cylinder sleeve (18). Pull

should be 6 lb (2.72 kg).

(c)

Minimum clearances will be 0.001 in.

(0.025 mm).

(d)

If clearance is greater than 0.0120 in.

(0.3048 mm), replace piston skirt (14).

5-112