137. Air Pressure Gage

a. Removal.

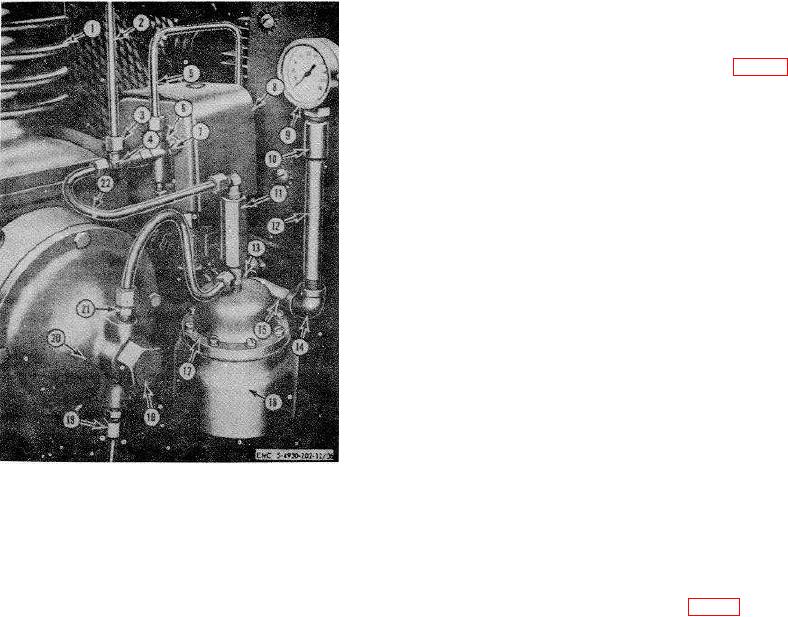

(1) Remove the air pressure gage (9, fig. 36)

from the pipe coupling (10).

(2) Remove the pipe coupling from the nipple

(12), and the nipple from the elbow (14).

(3) Remove the elbow from the straight

fitting, and the straight fitting from the

manifold.

b. Cleaning, Inspection, and Repair.

(1) Clean all parts, using an approved

cleaning solvent.

(2) Inspect the air pressure gage. See that

the air gage needle is not bent, that the

glass is not cracked or broken, and that

the case is undamaged.

Replace a

defective air pressure gage.

(3) Inspect all parts for bends, dents, cracks,

internal obstructions, or external wear.

Replace any defective parts.

c. Installation.

(1) Install the straight fitting in t he manifold.

(2) Install the elbow (14) in the straight fitting

and the nipple (12) to the elbow.

1

Cylinder

(3) Install the pipe coupling (10) into the

2

Throttle control air tube

nipple, and the air pressure gage (9) into

3

Connector

the pipe coupling.

4

Compression tee

(4) Test the air pressure gage line for leaks.

5

Tank control valve air tube

6

Two-way release valve

7

Screw, 1/4--28 x 3/8 in. (2 rqr)

138. Auxiliary Unloader Release Valve

8

Pressure switch

a. Removal.

9

Air pressure gage

(1) Disconnect the air tube (22, fig. 36) at the

10

Pipe coupling, 1/4 in. NPT

compression tee (4) and at the auxiliary

11

Auxiliary air release valve

unloader release valve (11).

12

Nipple, 1/4 in. NPT x 5 in.

13

Tee

(2) Disconnect the tubing (17) at the unloader

14

Elbow, 1/4 in. 90

cap (20) and at the tee (13).

15

Nipple, 3/8 x 3 1/2, in.

(3) Remove the elbow (23) from the auxiliary

16

Auxiliary unloader assembly

unloader release valve (11).

17

Tubing, 1/4 x 12 in.

(4) Remove the auxiliary unloader release

18

Unloading valve cap

valve from the auxiliary unloader

19

Bleeder tube

assembly (16).

20

Unloading cap

21

Straight connector

b. Cleaning, Inspection, and Repair.

22

Air tube

(1) Clean all parts, using an approved

23

Elbow

cleaning solvent.

Figure 36. Compressor air controls.

(2) Inspect the auxiliary unloader release

valve. If any parts are worn or defective,

(2) and the auxiliary release valve air tube

replace the auxiliary unloader release

(22) to the compression tee.

valve.

(4) Connect the tank control valve air tube (5)

to the two-way release valve.

76