CHAPTER 4

ORGANIZATIONAL

MAINTENANCE

INSTRUCTIONS

Section I. ORGANIZATIONAL PREVENTIVE MAINTENANCE SERVICES

4-1. General

tenance checks and services which must be performed

by organizational maintenance personnel. Item num-

Refer to paragraph 3-6 for the purpose of preventive

bers indicate the sequence of minimum inspection

maintenance checks and services.

requirements and the interval column designates

the required service intervals. A quarterly interval

4-2. Preventive Maintenance Services

is equal to three calendar months or 250 hours of

operation, whichever occurs first.

Table 4-1 contains a tabulated list of preventive main-

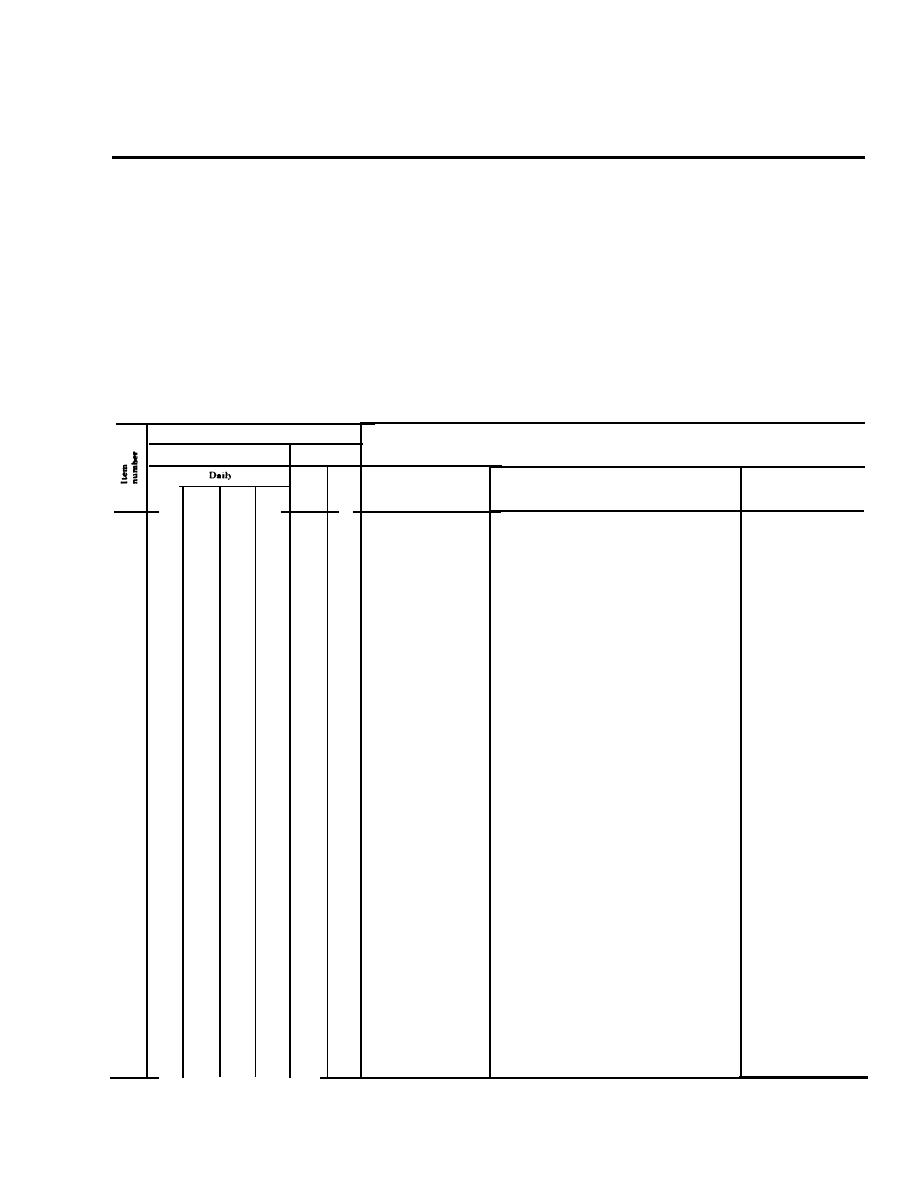

Table 4-1. Preventive Maintenance Checks and Services (Organizational)

Interval

MMonthly

B--before

operation

A--After operation

W -- Weekly

QQuarterly

D--During

operation

Operator

Org.

Reference

M

Q

Item to be inspected

Procedure

w

A

B

D

--

--

Para 4-43 and

x

1

Master cylinder and

Check for proper operation, leaks, loose

Para 4-44

fittings and secure mountings.

air brake chamber

x

TM 5-2805-203-14

2

Engine

Inspect engine for proper operation.

x

3

Carburetor and

Check carburetor and linkage to see

linkage

that they are in good condition, cor-

rectly installed and assembled. Check

carburetor for leaks. Make sure choke

valve opens fully when in released

TM 5-2805-203-14

position.

x

4

Fuel pump and fuel

Inspect fuel pump and fuel lines for

TM 5-2805-203-14

lines

leaks. Check for secure mounting.

Para 4-20

x

5

Fuel tank

Check fuel tank, lines and connections

for leaks.

TM 5-2805-203-14

x

Engine air cleaner

6

Check for secure mounting and loose

connections.

TM 5-2805-203-14

7

x

Engine oil filter

Inspect oil filter for secure mounting.

Inspect oil lines for leaks.

Para 3-18

8

Compressor air

Inspect for secure mounting and loose

cleaner

connections.

9

x

Lubricant pressure

Check for lubricant or air leaks at all

system

lines. Check swivel joints at hose

Paras 4-28 and

reel inlets.

4-35

x

10

Lubricant tanks

Inspect lubricant tanks for cleanliness

and leakage. Inspect tank cover to

Para 4-31

make sure it seals properly.

x

Para 4-30

11

Inspect lubricant pumps for leakage

Lubricant pumps

and secure mounting.

Para 4-34

Inspect pump hoses for leaks or other

damage.

Para 4-32

x

12

Lubricant valves

Inspect lubricant valves and meters

for proper operation.

and meters

x

Para 4-16

13

Inspect instrument panel for secure

Instrument panel

mounting. Inspect all gages and

switches for proper operation.

4-1