(2) Inspect the compressor flywheel pulley

for cracks or burrs. Replace a defective fly-

wheel pulley.

c. Installation. Install the flywheel pulley in

reverse of removal. Do not force pulley on

shaft. Be certain of alinement.

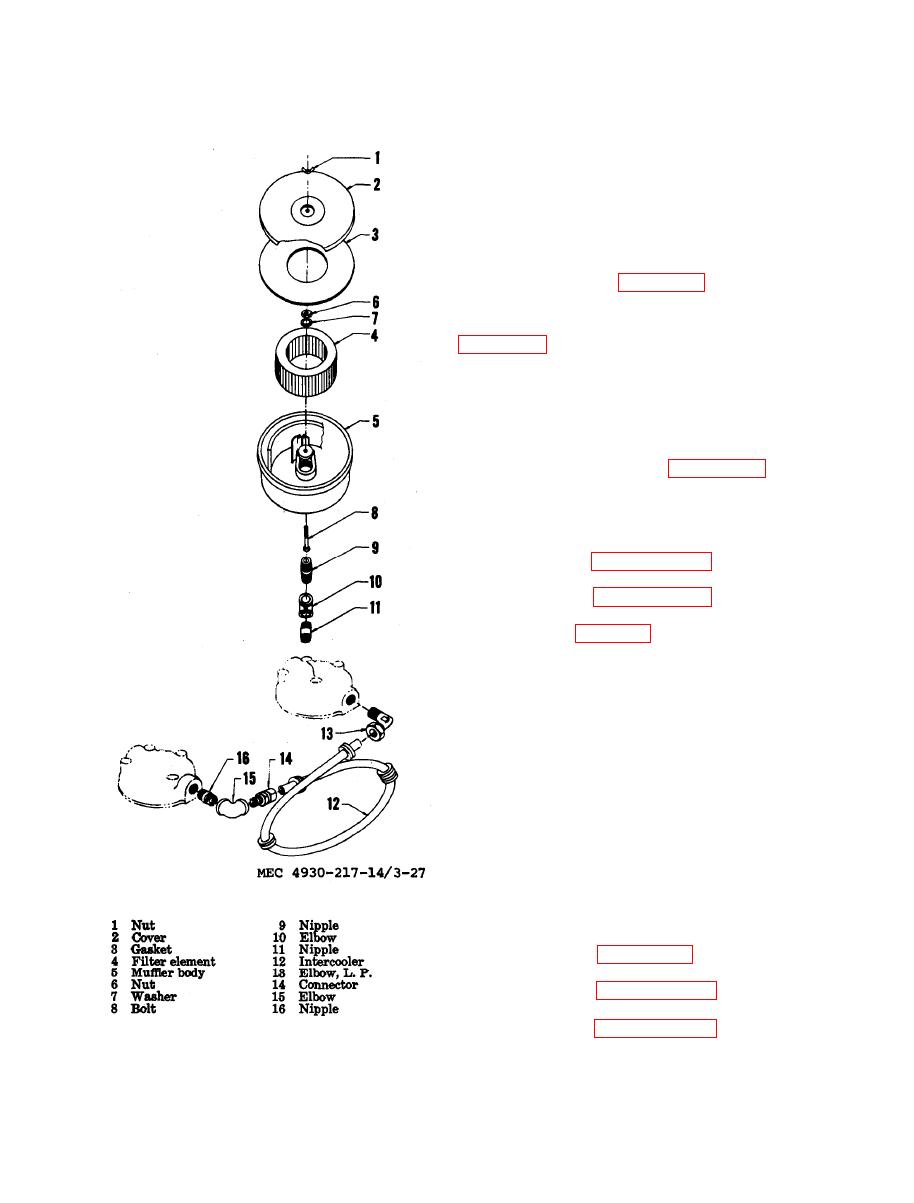

a. Removal. Refer to figure 3-26, and remove

the lines and intercooler.

b. Disassembly and Reassembly. Refer to

intercooler.

c. Inspection.

(1) Inspect the lines and intercooler for

cracks, burrs, excessive bends or other damage.

(2) Replace damaged or worn parts.

d. Installation. Refer to figure 3-26 and

install the intercooler and lines.

3-97. Compressor

a. Removal.

(1) Refer to paragraph 3-93 and remove

belt guard.

(2) Refer to paragraph 3-41 and remove

the drive belts.

(3) Refer to figure 3-26 and remove com-

pressor.

b. Inspection.

(1) Perform a thorough general inspec-

tion of all parts of the compressor assembly,

checking particularly for cracked and chipped

castings, damaged screw threads, and finished

surfaces that are scored, pitted, or scratched.

(2) Inspect connecting tube assemblies

and fittings for worn or damaged screw

threads, cracks, dents, sharp bends, and other

defects. Pay particular attention to the flare

ends of the tubes since cracking is most apt to

occur at the root of the flare. Do not attempt

to reclaim a connecting tube assembly by re-

placing component parts.

c. Installation.

(1) Refer to figure 3-26 and carefully

install compressor.

(2) Refer to paragraph 3-41 and install

compressor drive belt.

(3) Refer to paragraph 3-93 and install

belt guard.

disassebly and reassembly.