TM 5-4930-218-14

necessary.

(6) Inspect all other parts for cracks, distortion,

and damage. Replace defective parts.

(7) Reassemble and install parts as shown in

d. Air Receiver. Check that air receiver is drained

each time the compressor is shut down. Do not allow

moisture to collect in the air receiver. Drain the air

receiver by opening the air receiver drain valve (4,

System

a. Keep the lubricant dispensing system parts

clean and free from spilled lubricants. Wipe dispen-

sing equipment and hoses before stowing after use.

Clean spilled lubricants from the trailer and other

parts.

b. Inspect the dispensing hoses and nozzles for

d a m a g e . Report any damage you find to

organizational maintenance.

c. Before dispensing lubricants, be sure to open the

condensate valves (5, fig. 2-2) to drain any collected

moisture from the lubricant pumps.

a. Be sure that you keep all moisture drained from

the trailer brake system air reservoir. Open the reser-

voir drains at least once every operating period to ex-

pel any collected water.

b. Weekly, check the level of brake fluid in the

master brake cylinder. To assure safe brake

operation, you must keep the reservoir full. Remove

the filler plug and fill with brake fluid as directed in

LO 5-4930-218-12.

c. Daily, check tires for proper inflation, You must

maintain an air pressure of 50 psi.

U s e the tire chuck and gage provided

with t h e l u b r i c a t i n g a n d d i s p e n s i n g

u n i t t o check t i r e p r e s s u r e b e f o r e

towing the trailer.

d. Weekly, check tires for wear, cracks, cuts, im-

bedded stones or penetrating objects, or leaks. Report

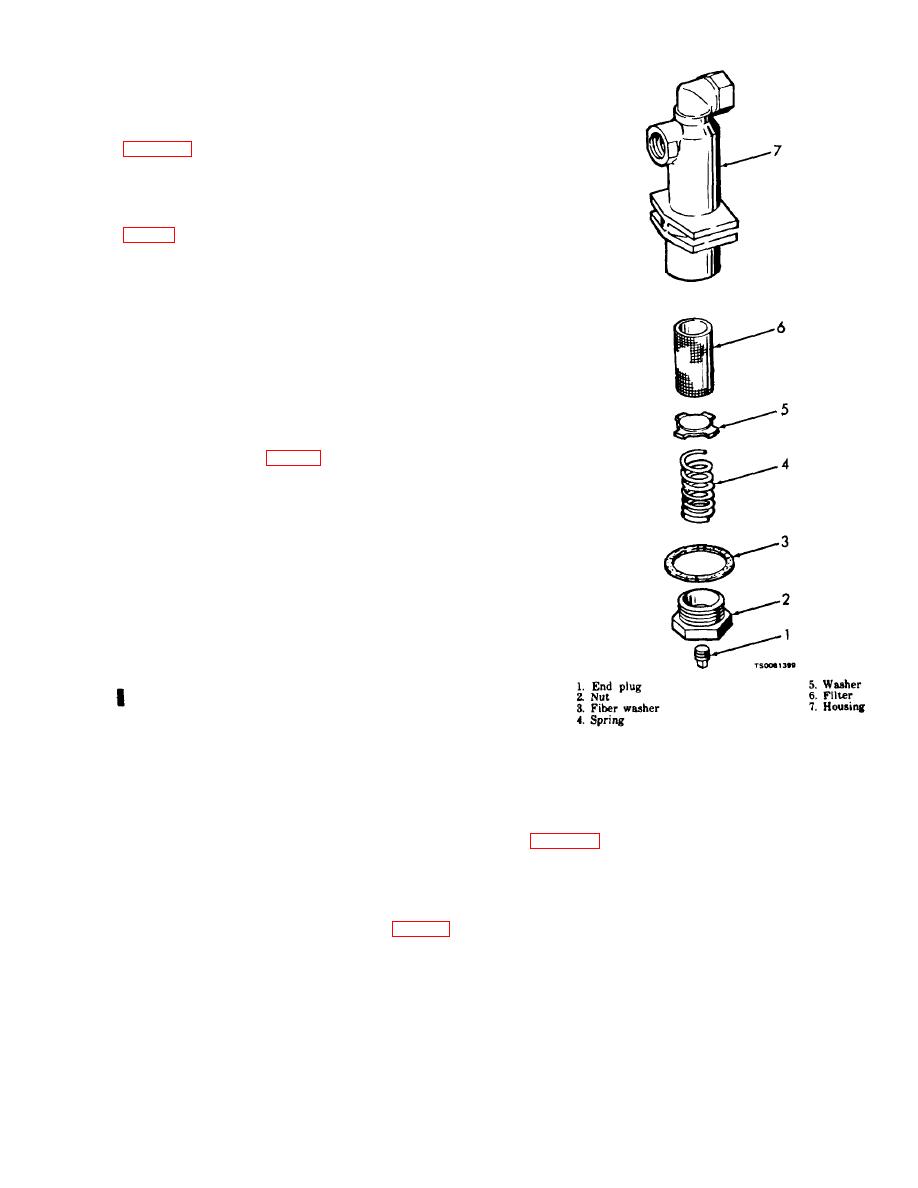

dry the filter. Reassemble the parts as shown in

damage to organizational maintenance.

e. Weekly, check springs for broken leaves and

check shock absorbers for leaks. Report any damage

3-14. Maintenance of Trailer Lighting

to organizational maintenance.

System

f. Service the trailer brake system air filter as

Before you tow the lubricating and dispensing

follows:

unit in traffic, check that the lighting system is

(1) Daily, remove the end plug (1, fig. 3-6) to

operating properly when the unit is connected to the

drain the collected moisture from the filter.

towing vehicle. Check that brake lights, directional

(2) Weekly, remove the nut (2) and fiber washer

signals, tail lights, and running lights are all func-

(3), and remove the spring (4), washer (5), and filter

tioning. Report malfunction to organizational main-

(6) from the housing (7) and wash all metallic parts

with dry cleaning solvent (fed. spec. P-D-680). Shake

tenance.

3-7/(3-8 Blank)

U.S.

GOVERNMENT

PRINTING

OFFICE:

1986

-

652-032/40287