TM 5-4930-218-14

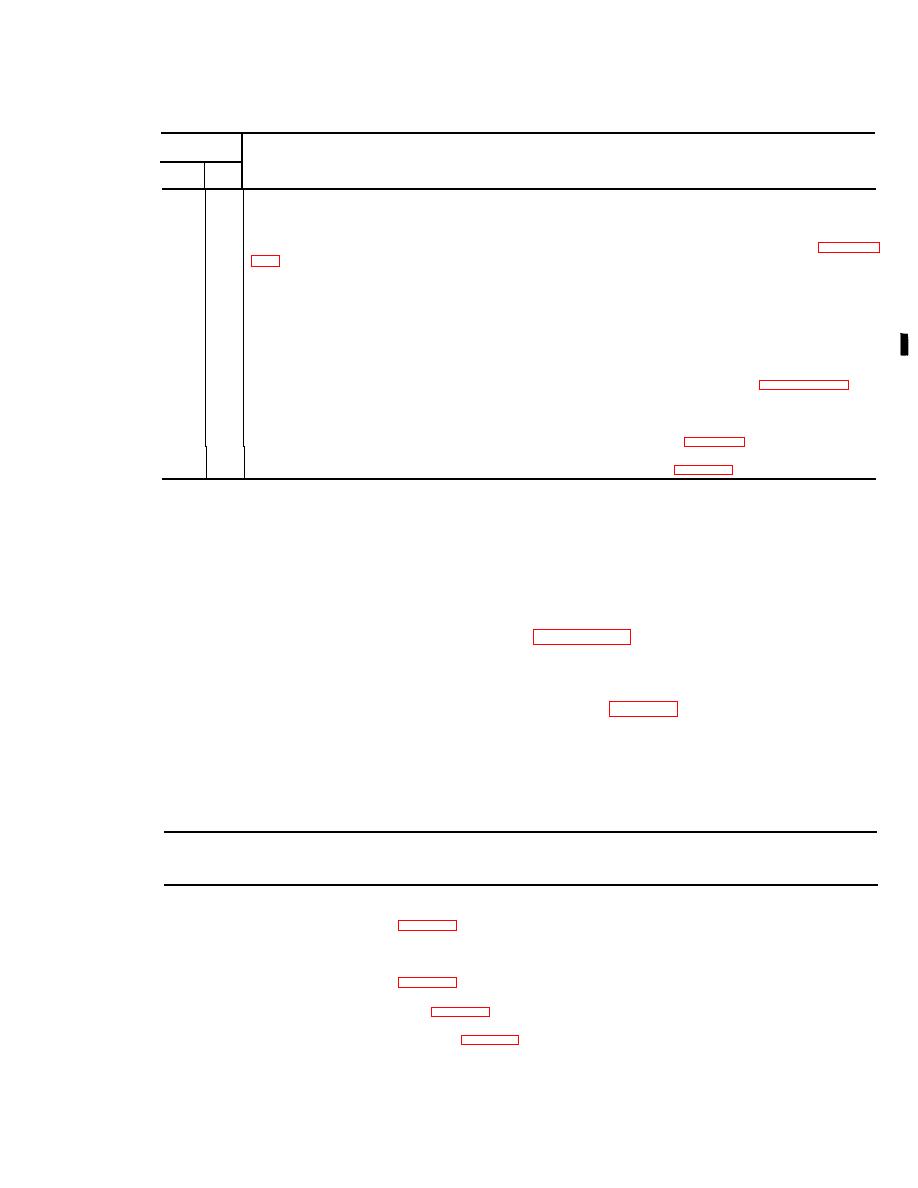

Table 4-1. Organizational Preventive Maintenance

Checks and Services-Continued

Q-Quarterly

M-Monthly

lnterval and

ITEM TO BE INSPECTED

Sequence No.

PROCEDURE

M

Q

7

ALTERNATOR DRIVE BELT

Check drive belt for improper tension and for damage or wear. Replace drive belt if damaged.

8

INSTRUMENT PANEL

Inspect for inoperative or illegible gages, defective switches, or damaged controls. Replace as required. Refer to paragraphs

BATTERIES

9

WARNING

bat-

Do not smoke or use an open flame in the vicinity when servicing the

teries. Batteries generate hydrogen gas, which is highly explosive.

Teat battery condition with a hydrometer. Replace batteries if they fail to take and maintain a charge.

Refer to TM 9-2610-200-20.

TIRES

10

Inspect tires for proper inflation and condition. Repair or replace tires as necessary. Refer to paragraph 4-57.

11

BRAKE SYSTEM AIR RESERVOIR

Check reservoir for dents, damage, and leaking. Check for e-inure mounting and fittings.

12

BRAKE MASTER CYLINDER

Check for secure mounting and proper operation. Repair if leaking or defective (para 4-64).

13

SPRINGS AND SHOCK ABSORBERS

Check for broken leaf springs or leaking shock absorbers. Replace if defective (para 4-69 and 4-70).

Section VI. TROUBLESHOOTING

ed by listed corrective actions, notify your supervisor.

4-12. General

a. This section contains organizational main-

c. Only those functions which are solely within the

tenance troubleshooting information for locating and

scope of organizational maintenance are listed. For

correcting moat of the operating troubles which may

troubleshooting procedures which are within the

develop in the lubricating and servicing unit. Each

scope of operator/crew maintenance, refer to

malfunction for an individual component, unit, or

system is followed by a list of tests or inspections

which will help you to determine probable causes and

4-13. Organizational Maintenance

corrective actions to take. You should perform the

Troubleshooting Chart

tests/inspections and corrective actions in the order

Refer to table 4-2 for troubleshooting which is

listed.

allocated to organizational maintenance levels.

b. This manual cannot list all malfunctions that

NOTE

may occur, nor all tests or inspections and corrective

Before you use this table, be sure you have performed

actions. If a malfunction is not listed or is not correct-

all applicable operating checks.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

ENGINE FAILS TO TURN OVER WHEN STARTING BUTTON IS DEPRESSED.

Step 1. Check for a weak or dead battery.

Charge or replace battery (para 4-23).

Step 2. Inspect for loose or broken battery cables.

Tighten or replace broken battery cables.

Check for faulty starter pushbutton.

Step 3.

Replace faulty pushbutton (para 4-29).

Check for defective starting motor.

Step 4.

Replace defective starting motor (para 4-24).

Step 5. Check for internal seizure of the engine or compressor.

Replace engine or compressor if seized (para 4-38 or 4-42).