TM 9-4310-397-14

6-10. CONNECTING ROD, PISTONS, RINGS, AND LINERS AND CYLINDER BLOCK INSPECTION AND

REPAIR. - Continued

(2)

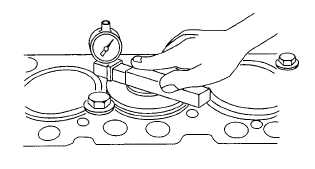

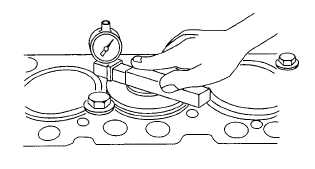

Measure cylinder height (Figure 6-69). Use a dial indicator and gauge (item 22, section III, appendix B).

NOTE

Variations in measurement readings may occur within one cylinder and/or

between adjacent cylinders.

Figure 6-69. Measure Cylinder Height

(a)

Measure each liner in four places, approximately at 1, 5, 7, and 11 o'clock positions as viewed from

the rear of the engine (flywheel end). Record all measurements. Liner height Specifications are as

follows:

1

Liner height above block 0.0004 - 0.004 in. (0.01-0.10 mm). NW

2

Maximum permissible difference between readings within one cylinder or between adjacent

cylinders 0.002 in. (0.06 mm).

3

If liner height is less than minimum specified, one liner shim may be installed on bottom of liner

flange. Two sizes of shims are available 0.002 in. (0.05 mm) and 0.004 in. (0.10 mm).

(b)

Remove cap screws and washers securing liners to cylinder block.

NOTE

Each cylinder liner must be reinstalled in cylinder bore from which it was

removed.

(c)

Number cylinder liners and pistons. Stamp front of liner to assure correct assembly. Do not stamp

liner flange; stamp on fire dam only.

6-58